videos

XEPOX - MAKES TIMBER STRONGER THAN WOOD

CAP SUPER - ADJUSTABLE ROOFING SYSTEM FOR CONSTRUCTION SITES

STRUCTURAL RESTORATION: INNOVATING TO RECOVER EXISTING BUILDING STOCK

More than ever before, it is important to propose recovery solutions for renovating the existing building stock according to economically sustainable, environmentally friendly and energy efficient logics.

The reinforcement works that are designed and carried out must perfectly combine different factors, such as seismic improvement and increase of the deck strength and stiffness, while respecting the principles of conservative restoration (material compatibility, reversibility and non-invasiveness of the intervention) and the need for good acoustic insulation between the various decks.

Conscious of our role as innovators, we have developed specific systems for the recovery of existing structures by timber-to-timber and timber-to-concrete reinforcement. These technologically advanced solutions include a wide range of high-strength and high-stiffness connectors, protective membranes, adhesive insulators and other accessories.

The reinforcement works that are designed and carried out must perfectly combine different factors, such as seismic improvement and increase of the deck strength and stiffness, while respecting the principles of conservative restoration (material compatibility, reversibility and non-invasiveness of the intervention) and the need for good acoustic insulation between the various decks.

Conscious of our role as innovators, we have developed specific systems for the recovery of existing structures by timber-to-timber and timber-to-concrete reinforcement. These technologically advanced solutions include a wide range of high-strength and high-stiffness connectors, protective membranes, adhesive insulators and other accessories.

RECREATE TIMBER WITH SUPERIOR PERFORMANCE

The XEPOX range of products, our two-component epoxy resins for structural applications, is one of the leading solutions for building renovation.

High performing and reliable, they are ideal for static reinforcement, timber reconstruction and making rigid joints, providing a simple and flexible way to create effective and long-lasting timber-to-steel joints.

XEPOX resins are composed of high-quality epoxy and amine components to ensure outstanding mechanical, chemical and physical properties.

They are characterised by significantly higher tensile and shear strengths than timber. These strengths remain unchanged over time, ensuring the durability of the structure.

High performing and reliable, they are ideal for static reinforcement, timber reconstruction and making rigid joints, providing a simple and flexible way to create effective and long-lasting timber-to-steel joints.

XEPOX resins are composed of high-quality epoxy and amine components to ensure outstanding mechanical, chemical and physical properties.

They are characterised by significantly higher tensile and shear strengths than timber. These strengths remain unchanged over time, ensuring the durability of the structure.

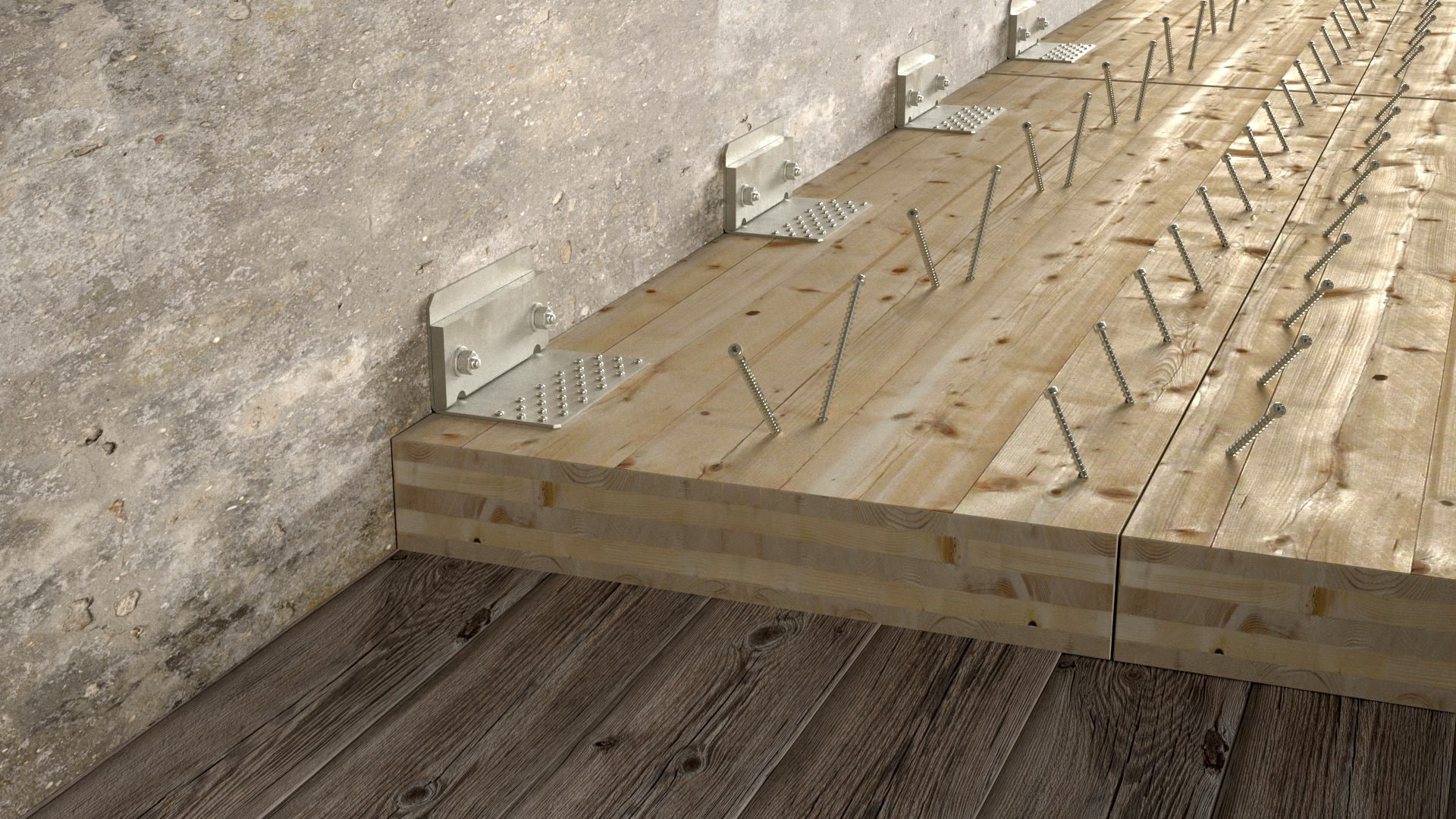

INCREASE STIFFNESS WITH COMPOSITE FLOORS

One of the most effective methods of reinforcing an existing timber floor is to increase its structural stiffness. A more rigid floor also reduces the transmission of acoustic vibrations through the timber elements and also limits the vertical deformation of the existing beams.

One of the fastest and most effective ways to achieve this increase in stiffness is through the use of collaborative floors, which can be realised with two different systems:

Both solutions guarantee compliance with the principles of conservative restoration, which is fundamental in the recovery of traditional architectural heritage, and can be calculated using our MyProject software.

One of the fastest and most effective ways to achieve this increase in stiffness is through the use of collaborative floors, which can be realised with two different systems:

- timber-to-timber composite floor connected by full thread crossed connectors VGZ;

- timber-to-concrete composite floor connected by double thread crossed connectors CTC.

Both solutions guarantee compliance with the principles of conservative restoration, which is fundamental in the recovery of traditional architectural heritage, and can be calculated using our MyProject software.

STRUCTURAL RESTORATION AND ENERGY EFFICIENCY

Our laboratory tests have shown the importance of using variable diffusion membranes in the drying of a stratigraphy following the moisture accumulation phases typical of building restoration processes.

Membranes such as CLIMA CONTROL are ideal in this sense, as they allow the structure to dry out in the months following processing, acting as vapour brakes once thermal balance has been reached.

In order to verify this behaviour, we have set up an initial measurement phase in the laboratory. After a conditioning phase in which the different layers were kept at high humidity (80%), the test phase was started under dynamic outdoor conditions in which the conditions of a central European summer climate (Munich) were reproduced. Already after 17 days, it was possible to notice the drying process and the decrease of moisture content within the layers.

With the right solutions it is easy to create buildings that do not waste energy resources, with the correct humidity and temperature conditions: the better we use these technologically researched products, the less resources we waste and the more we protect the environment.

Membranes such as CLIMA CONTROL are ideal in this sense, as they allow the structure to dry out in the months following processing, acting as vapour brakes once thermal balance has been reached.

In order to verify this behaviour, we have set up an initial measurement phase in the laboratory. After a conditioning phase in which the different layers were kept at high humidity (80%), the test phase was started under dynamic outdoor conditions in which the conditions of a central European summer climate (Munich) were reproduced. Already after 17 days, it was possible to notice the drying process and the decrease of moisture content within the layers.

With the right solutions it is easy to create buildings that do not waste energy resources, with the correct humidity and temperature conditions: the better we use these technologically researched products, the less resources we waste and the more we protect the environment.