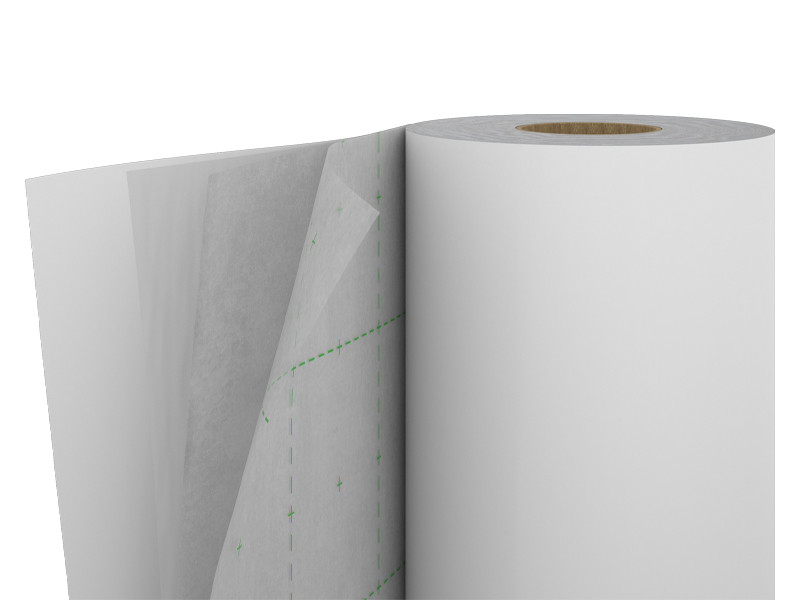

SELF-ADHESIVE PROTECTIVE MEMBRANE

DEFENCE ADHESIVE 200

DEFENCE ADHESIVE 200 self-adhesive membrane is ideal for protecting timber construction elements during transport and construction. Protection is guaranteed for 12 weeks. The product, once applied, is invisible and allows both the markings of the powder tracer on the panel and the mounting holes to be easily seen.

The membrane protects the timber without interfering with either handling or site operations. The surface treatment makes the product waterproof.

Videos

Self-adhesive, non-slip waterproofing membrane

The surface treatment makes the product waterproof. On site, the membrane resists abrasion and trampling. With the self-adhesive surface of the membrane, installation is quick and easy. In case of a mistake during installation, the membrane can be repositioned and reapplied without difficulty. Protection of building elements is guaranteed for 12 weeks.

Self-adhesive waterproof sheathing with good vapour permeability

The special polymer treatment makes the membrane impermeable to water and air, but with adequate vapour permeability. This makes it easier for any seepage to dry out.

Use

DEFENCE ADHESIVE 200 is an adhesive waterproofing sheath ideal for prefabrication: installation on the panel is improved and protection of the building element during transport and assembly is maximized. Highly flexible and repositionable, the membrane ensures sealing of complex surfaces.

In summary

DEFENCE ADHESIVE 200 is an innovative membrane from Rothoblaas, designed to ensure flawless protection of timber construction elements during transport and construction. With its lightweight 200 g/m2 thickness, this self-adhesive membrane offers quick and easy application, reducing installation time. Its state-of-the-art formulation makes it highly resistant to weathering, with 12 week guaranteed protection. DEFENCE ADHESIVE 200 is the perfect choice for users seeking a high-performance and efficient solution for the protection of building elements.

Documents

| Technical data sheets |

|---|

DEFENCE ADHESIVE 200

| CODE | description | g/m² | liner | H

[m]

|

L

[m]

|

A

[m²]

|

pcs./pallet |

|---|---|---|---|---|---|---|---|

| DEFA200 | DEFENCE ADHESIVE 1.55m | 220 | 150/1400 | 1.55 | 50 | 77.5 | 22 |

| DEFAS200 | DEFENCE ADHESIVE 200 STRIPE | 220 | 192.5/192.5 | 0.385 | 50 | 19.25 | - |

| DEFA200490 | DEFENCE ADHESIVE 50 cm | 220 | 245/245 | 0.49 | 50 | 24.5 | 72 |

| DEFA200990 | DEFENCE ADHESIVE 1m | 220 | 495/495 | 0.99 | 50 | 49.5 | 30 |

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 200 g/m² | 0.66 oz/ft² |

| Thickness | EN 1849-2 | ca. 0,25 mm | ca. 10 mil |

| Water vapour transmission (Sd) | EN 1931 | 2,5 m | 1.399 PERM |

| Resistance to nail tearing MD/CD | EN 12310-1 | > 60 / 65 N | > 13 / 15 lbf |

| Watertightness | EN 1928 | conforming | - |

| Thermal resistance | - | -40 / 80 °C | -40 / 176 °F |

| Reaction to fire | EN 13501-1 | class E | - |

| Density | - | ca. 800 kg/m³ | - |

| Water vapour resistance factor (μ) | - | ca. 10000 | - |

| Exposure to weather | - | 12 weeks | - |

| Elongation MD/CD | EN 12311-1 | > 40 / 40 % | - |

| Tensile strength MD/CD | EN 12311-1 | > 120 / 80 N/50mm | > 14 / 9 lb/in |

| Application temperature | - | 5 / 25 °C | 41 / 77 °F |

| Storage temperature (1) | - | -5 / 35 °C | 23 / 95 °F |

Specifications

Supply and installation of vapour control membrane, type DEFENCE ADHESIVE 200

Composition:

- EVA coating and PP protection layer

Properties:

- Mass per unit area (g/m2) : 200

- Water vapour transmission (Sd) (m) : 2,5

- Tensile strength MD/CD (N/50mm) : >120/80

- Elongation MD/CD (%) : >40/40%

- Resistance to nail tearing MD/CD (N) : >60/65

- Watertightness (class) : conforme

- Water column (cm) : -

- VOC emissions (COV) (% (class A+)) : -

- Driving rain test : -

- UV resistance with open joints up to 50 mm wide exposing no more than 40 % of the surface : -

- Temperature resistance (°C) : -40/+80

- Reaction to fire (class) : E

CE marking in accordance with EN 13984

DEFENCE ADHESIVE 200 it can be used for temporary protection.

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

During application, pressure must be applied to the membrane to ensure proper adhesion. To prevent rainwater accumulation on the membrane, it is necessary to design the building water drainage. 15 cm of overlap. Possibility of waterproofing the element joint using INVISI60/100/200 wide pre-cut tapes.

Composition

| TOP LAYER | EVA functional film |

|---|---|

| BOTTOM LAYER | non-woven PP fabric |

| GLUE | acrylic dispersion without solvents |

| RELEASE LINER | removable plastic film |