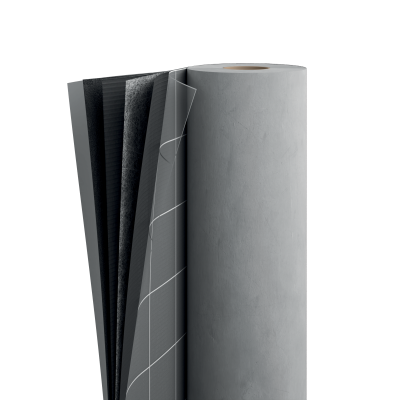

BYTUM BASE 2500

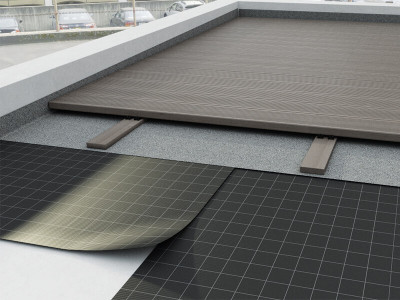

The BYTUM BASE 2500 self-adhesive bituminous membrane is the ideal solution on flat roofs in combination with the BYTUM SLATE 3500 slated membrane as the final visible layer. The polymer-modified bituminous compound ensures flexibility and workability even at low temperatures, and allows installation without the use of naked flames or heat.

Description

BYTUM BASE 2500, the self-adhesive bituminous membrane that simplifies installation.

The screen-printed film makes installation extremely easy. The adhesive compound and the polyester surface finish allow perfect self-sealing of the membrane. Used on slopes up to 5° as an underlay, this adhesive bituminous membrane guarantees excellent water tightness.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Recommendations for installation

- Recommendations for installation Chinese

- Recommendations for installation Czech

- Recommendations for installation Dutch

- Recommendations for installation English

- Recommendations for installation French

- Recommendations for installation German

- Recommendations for installation Greek

- Recommendations for installation Hungarian

- Recommendations for installation Italian

- Recommendations for installation Japanese

- Recommendations for installation Korean

- Recommendations for installation Polish

- Recommendations for installation Portuguese

- Recommendations for installation Romanian

- Recommendations for installation Russian

- Recommendations for installation Slovene

- Recommendations for installation Spanish

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-1 | ca. 2650 g/m² | ca. 8.68 oz/ft² |

| Thickness | EN 1849-1 | 2 mm | 79 mil |

| Water vapour transmission (Sd) | EN 1931 | ca. 200 m | ca. 0.017 US perm |

| Tensile strength MD/CD | EN 12311-1 | 400 / 300 N/50mm | 46 / 34 lbf/in |

| Elongation MD/CD | EN 12311-1 | 35 / 35 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | 120 / 120 N | 27 / 27 lbf |

| Watertightness | EN 1928 | 60 kPa | - |

| Resistance to temperature | - | -20 / 90 °C | -4 / 194 °F |

| Reaction to fire | EN 13501-1 | class E | - |

| Thermal conductivity (λ) | - | 0,17 W/(m·K) | 0.1 BTU/(h·ft·°F) |

| Specific heat | - | 170 J/(kg·K) | - |

| Density | - | ca. 1250 kg/m³ | - |

| Water vapour resistance factor (μ) | - | ca. 20000 | - |

| Joint strength | EN 12317-2 | 300 / 200 N/50mm | 34.260883 / 22.840589 lb/in |

| After artificial ageing - Tensile strength MD/CD | EN 1297 / EN 12311-1 | 300 / 200 N/50mm | 34 / 23 lb/in |

| After artificial ageing - elongation | EN 1297 / EN 12311-1 | 30 / 30 % | - |

| Flexibility at low temperatures | EN 1109 | - | - |

| Hot sliding | EN 1110 | 90 °C | 194 °F |

| Flexibility at low temperatures | EN 1109 | - | - |

| Storage temperature | - | 10 / 40 °C | 50 / 104 °F |

| Application temperature | - | 10 / 30 °C | 50 / 86 °F |

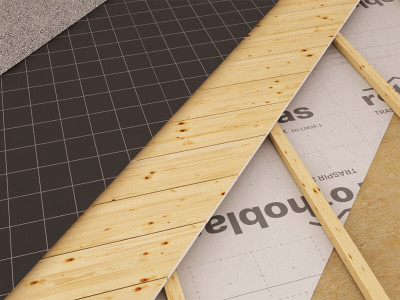

Composition

| TOP LAYER | PL film |

|---|---|

| compound | elastoplastic polymeric distilled bitumen |

| REINFORCING LAYER | PL stabilised with fibreglass |

| compound | elastoplastic polymeric distilled bitumen |

| Adhesive layer | distilled bitumen modified with self-adhesive polymer |

| RELEASE LINER | removable plastic film |

Specifications

BYTUM BASE 2500

Supply and installation of self-adhesive bituminous membrane, type BYTUM BASE 2500.

Composition

From top layer to bottom layer:

-

PL film;

-

elastoplastic polymeric distilled bitumen;

-

PL stabilised with glass fibre;

-

elastoplastic polymeric distilled bitumen;

-

distilled bitumen modified with self-adhesive polymer;

-

removable plastic film.

Properties

-

Mass per unit area [g/m²]: approx. 2650

-

Thickness [mm]: 2

-

Water vapour transmission (Sd) [m] approx. 200

-

Tensile strength MD/CD [N/50 mm]: 400/300

-

Elongation MD/CD [%]: 35/35

-

Resistance to nail tearing MD/CD [N]: 120/120

-

Watertightness (60 kPa): comply with (EN 1928)

-

Resistance to temperature [°C]: -20/+90

-

Reaction to fire: class E (EN 13501-1)

-

Thermal conductivity (λ) [W/(m·K)]: 0,17

-

Density [kg/m3]: approx. 1250

-

UV stability: 336 h (3 months)

-

Storage temperature [°C]: +10/+ 40

Standards and certifications

-

CE marked in accordance with EN 13707

-

AUS 4200.1 Class 1

Description

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

The screen-printed film makes installation extremely easy. The adhesive compound and the polyester surface finish allow perfect self-sealing of the membrane.

Recommended use: The membrane is designed for applications on the exterior side of the roof.

Used on slopes from 5° as an underlay, this adhesive bituminous membrane guarantees excellent water tightness.

Installation:

Unroll the membrane over the surface, progressively remove the release film from the adhesive, and press the membrane firmly to ensure proper adhesion.

Once membrane installation is complete, a pressure roller must be used to ensure perfect adhesion.

In cold climates, the adhesive side of the membrane can be preheated using a hot air gun, such as HOT GUN, to achieve optimal bonding.