BYTUM SLATE 3500

BYTUM SLATE 3500 is the reinforced bituminous membrane that ensures effective waterproofing of timber structures and, thanks to its slated surface, it ensures permanent stability to UV rays.

It consists of distilled bitumen with elastoplastic polymers and a slate coating, and is designed for application on the external side of the roof.

Description

BYTUM SLATE 3500, EFFECTIVE WATERPROOFING AND PERMANENT UV STABILITY

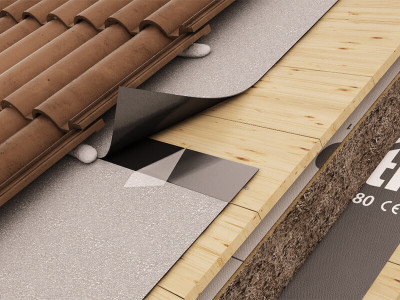

BYTUM SLATE 3500 can be used for flat roofs as the final visible layer in combination with the self-adhesive and self-sealing sheath, BYTUM BASE 2500, for optimal waterproofing.

Can be used as an underlay also for low-pitched roofs. Guaranteed flexibility and workability even at low temperatures ensure easy installation.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

BYTUM SLATE 3500

| CODE | description | liner | colour | H

[m]

|

L

[m]

|

A

[m²]

|

H

[ft]

|

L

[ft]

|

A

[sft]

|

pcs./pallet |

DOP

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| BYTSWHI3500 | BYTUM SLATE 3500 WHITE | 500/500 | WHITE | 1 | 10 | 10 | 3' 3 3/8'' | 33 | 108 | 20 | |

| BYTSGRE3500 | BYTUM SLATE 3500 GREEN | 500/500 | GREEN | 1 | 10 | 10 | 3' 3 3/8'' | 33 | 108 | 20 | |

| BYTSRED3500 | BYTUM SLATE 3500 RED | 500/500 | RED | 1 | 10 | 10 | 3' 3 3/8'' | 33 | 108 | 20 | |

| BYTSGRA3500 | BYTUM SLATE 3500 GREY | 500/500 | GREY | 1 | 10 | 10 | 3' 3 3/8'' | 33 | 108 | 20 |

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-1 | 3500 g/m² | 11.47 oz/ft² |

| Thickness | EN 1849-1 | ca. 2,8 mm | ca. 110 mil |

| Water vapour transmission (Sd) | EN 1931 | 280 m | 0.012 US perm |

| Tensile strength MD/CD | EN 12311-1 | 400 / 300 N/50mm | 46 / 34 lbf/in |

| Elongation MD/CD | EN 12311-1 | 35 / 35 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | 120 / 120 N | 27 / 27 lbf |

| Adhesion strength on steel | ASTM D3330 | 50 N/10mm | 28.55 lbf/in |

| Joint separation resistance MD/CD | EN 12316-1 | 50 N/50mm | 5.71 lbf/in |

| Watertightness | EN 1928 | 60 kPa | - |

| Resistance to temperature | - | -20 / 90 °C | -4 / 194 °F |

| Flexibility at low temperatures | EN 1109 | - | - |

| Hot sliding | EN 1110 | 90 °C | 194 °F |

| Application temperature (ambient, cartridge and support) | - | 10 / 30 °C | 50 / 86 °F |

| Reaction to fire | EN 13501-1 | class E | - |

| Thermal conductivity (λ) | - | 0,17 W/(m·K) | 0.1 BTU/(h·ft·°F) |

| Specific heat | - | 170 J/(kg·K) | - |

| Density | - | ca. 1250 kg/m³ | - |

| Water vapour resistance factor (μ) | - | ca. 20000 | - |

| Joint strength | EN 12317-2 | 300 / 200 N/50mm | 34.260883 / 22.840589 lb/in |

| Watertightness after artificial ageing | EN 1297 / EN 1928 | compliant | - |

| After artificial ageing - Tensile strength MD/CD | EN 1297 / EN 12311-1 | 300 / 200 N/50mm | 34 / 23 lb/in |

| Storage temperature | - | 10 / 40 °C | 50 / 104 °F |

| After artificial ageing - elongation | EN 1297 / EN 12311-1 | 30 / 30 % | - |

| Flexibility at low temperatures | EN 1109 | - | - |

| UV stability | - | Permanent | - |

Composition

| TOP LAYER | slate chips |

|---|---|

| compound | elastoplastic polymeric distilled bitumen |

| REINFORCING LAYER | PL stabilised with fibreglass |

| compound | elastoplastic polymeric distilled bitumen |

| Adhesive layer | distilled bitumen modified with self-adhesive polymer |

| RELEASE LINER | removable plastic film |

Specifications

BYTUM SLATE 3500

Supply and installation of self-adhesive bituminous slate-surfaced membrane, type BYTUM SLATE 3500.

Composition

From top layer to bottom layer:

-

slate chips;

-

elastoplastic polymeric distilled bitumen;

-

PL stabilised with glass fibre;

-

elastoplastic polymeric distilled bitumen;

-

distilled bitumen modified with self-adhesive polymer;

-

removable plastic film.

Properties

-

Mass per unit area [g/m²]: 3500

-

Thickness [mm]: approx. 2,8

-

Water vapour transmission (Sd)[m]: 280

-

Tensile strength MD/CD [N/50 mm]: 400/300

-

Elongation MD/CD [%]: 35/35

-

Resistance to nail tearing MD/CD [N]: 120/120

-

Watertightness (60 kPa): comply with (EN 1928)

-

Resistance to temperature [°C]: -20/+90

-

Reaction to fire: class E (EN 13501-1)

-

Thermal conductivity (λ) [W/(m·K)]: 0,17

-

Density [kg/m3]: approx. 1250

-

UV stability: permanent

-

Storage temperature [°C]: +10/+ 40

Standards and certifications

-

CE marked in accordance with EN 13707, EN 13859-1

-

AUS 4200.1 Class 1

Description

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

Guaranteed flexibility and workability even at low temperatures ensure easy installation.

The exposed slated top layer provides long-lasting weather resistance by protecting the bitumen waterproof layer.

Recommended use: The membrane is designed for applications on the exterior side of the roof.

Used on slopes from 5° as an underlay, this adhesive bituminous membrane guarantees excellent water tightness.

Installation:

Unroll the membrane over the surface, progressively remove the release film from the adhesive, and press the membrane firmly to ensure proper adhesion.

Once membrane installation is complete, a pressure roller must be used to ensure perfect adhesion.

In cold climates, the adhesive side of the membrane can be preheated using a hot air gun, such as HOT GUN, to achieve optimal bonding