CLIMA CONTROL 105

CLIMA CONTROL 105 is the variable diffusion membrane with a highly variable vapour diffusion resistance (0.1 - 20 m), which gives the product the ability to adapt to the hygrometric conditions of the structure, depending on the interstitial relative humidity: in the case of high amounts of moisture, it behaves like a more breathable membrane, facilitating the structure drying.

Description

CLIMA CONTROL 105, the membrane that prevents the accumulation of moisture within the building component thanks to its ability to dry.

The special PA film ensures maximum protection for walls and excellent security insulation, guaranteeing great reliability. Due to its transparency, the membrane is immediately installed on the substructure for a smooth and easy application.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Xml-File WUFI

-

Recommendations for installation

-

TEST REPORT USA-CA

-

Recommendations for installation: Internal membranes

- Recommendations for installation: Internal membranes English

- Recommendations for installation: Internal membranes French

- Recommendations for installation: Internal membranes German

- Recommendations for installation: Internal membranes Italian

- Recommendations for installation: Internal membranes Spanish

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 105 g/m² | 0.34 oz/ft² |

| Thickness | EN 1849-2 | 0,4 mm | 16 mil |

| Variable water vapour transmission (Sd) | EN 1931 / EN ISO 12572 | 0,1 / 20 m | 34.965 / 0.175 US perm |

| Water vapour transmission (dry cup) | ASTM E96/ E96M | 0.28 US perm | - |

| Water vapour transmission (dry cup) | ASTM E96/ E96M | 16 ng/(s·m²·Pa) | - |

| Tensile strength MD/CD | EN 12311-2 | > 175 / 150 N/50mm | > 20 / 17 lbf/in |

| Elongation MD/CD | EN 12311-2 | > 60 / 60 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | > 140 / 150 N | > 31 / 34 lbf |

| Watertightness | EN 1928 | - | - |

| Resistance to temperature | - | -40 / 80 °C | -40 / 176 °F |

| Reaction to fire | EN 13501-1 | class E | - |

| Resistance to penetration of air | EN 12114 | 0 m³/(m²·h·50Pa) | 0 cfm/ft² at 50Pa |

| Resistenza al vapore d'acqua dopo invecchiamento artificiale | EN 1296 / EN 1931 | compliant | - |

| Alkaline water vapour resistance | EN 1847 / EN 12311-2 | npd | - |

| Thermal conductivity (λ) | - | 0,2 W/(m·K) | 0.12 BTU/(h·ft·°F) |

| Specific heat | - | 1700 J/(kg·K) | - |

| Density | - | ca. 263 kg/m³ | - |

| Variable water vapour resistance factor (μ) | - | 250 / 50000 | - |

| VOC | - | not relevant | - |

Composition

| TOP LAYER | PA functional film |

|---|---|

| BOTTOM LAYER | non-woven PP fabric |

Specifications

CLIMA CONTROL 105

Supply and installation of membrane with variable vapour diffusion, like CLIMA CONTROL 105.

Composition

From top layer to bottom layer:

PA functional film;

non-woven PP fabric.

Properties

Mass per unit area [g/m²]: 105

Thickness [mm]: 0,4

Water vapour transmission (Sd)[m]: 0,1/20

Tensile strength MD/CD [N/50 mm]: > 175/150

Elongation MD/CD [%]: > 60/60

Resistance to nail tearing MD/CD [N]: > 140/150

Reaction to fire: class E (EN 13501-1)

Resistance to temperature [°C]: -40/80

Indirect exposure to UV rays≥: 2 weeks

VOC: not applicable

Standards and certifications

CE marked in accordance with EN13984

AUS 4200.1 Class2 - Class 4

ASTM

Description

The application surface must be dry, free of dust and grease. Surface elements must be removed so that the membrane is not damaged during application.

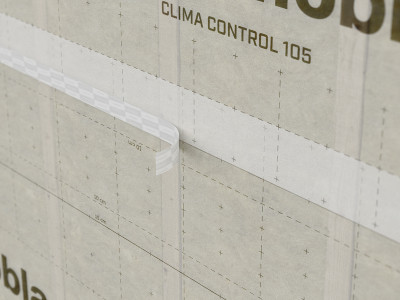

Once applied, the product allows for easy visibility of powder tracer markings and underlying mounting holes.

Recommended use: This product is intended for installation on the interior side of the building envelope and is guaranteed to withstand only indirect UV exposure for a maximum duration of 2 weeks.

Suitable for energy retrofit applications due to its ability to dynamically adapt to relative humidity. It is breathable when internal relative humidity is too high, and serves as a vapour control layer when internal humidity is at suitable levels.

Installation: Unroll the membrane and seal using tape such as: INVISI BAND, FLEXY BAND, SPEEDY BAND o EASY BAND.

Ensure that the overlap between the membranes is at least 15 cm to achieve an optimal seal.

Each layer must be fixed to the substrate with a mechanical fastening device to ensure installation stability.

To ensure correct and professional installation, the use of a nail sealing point is required.

Further details regarding installation can be found in the specific instructions provided by the supplier.