TRASPIR EVO SEAL 200

The TRASPIR EVO SEAL 200 is a highly breathable monolithic weather resistant barrier (WRB) engineered to deliver superior durability and waterproofing performance.

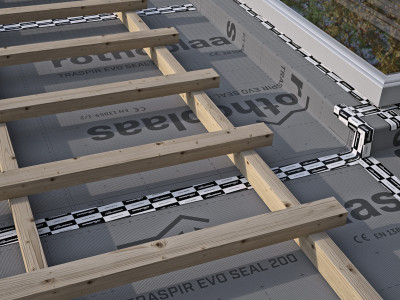

Engineered as a sheet roof membrane, it features enhanced puncture resistance against screws, nails, and staples.

This reliability is confirmed by rigorous testing and compliance with EAD 030218-01-0402, ÖNORM B3647 and ASTM D1970, validating its ability to self-seal around fasteners.

The oversized TPU film, significantly thicker than standard products, ensures long-lasting waterproofing even in the event of punctures, eliminating the need for additional sealing products. This makes installation fast, efficient and highly reliable on-site.

Description

Puncture-Resistant Roof Membrane

TRASPIR EVO SEAL 200 is a puncture-resistant, highly breathable monolithic WRB membrane developed for robust protection in the most demanding jobsite conditions.

The modified TPU film, with oversized thickness compared to industry standards, withstands drilling by screws and nails, ensuring the high-performance reliability of this monolithic sheet-applied solution.

Its specially formulated functional film provides outstanding long-term mechanical strength and weather resistance, while the external non-woven layers increase overall mechanical performance, delivering extra protection, abrasion resistance and stability against foot traffic. The protective layer also improves grip and safety for installers walking on the surface.

Designed to maintain high performance across all climate zones, TRASPIR EVO SEAL 200 guarantees durability and weather protection over time. Tested for full exposure, it functions as a temporary roof underlayment for up to 12 weeks during the construction phase.

Finally, TRASPIR EVO SEAL 200 belongs to a sustainable product line, supported by EPD and LCA declarations, offering verified data for green building compliance.

What is a breathable membrane and why is it important for roofs?

A breathable membrane is a protective layer that blocks external water while allowing internal vapor to escape.

In roofing applications, it prevents condensation, improves durability, and ensures energy efficiency. A roof membrane like TRASPIR EVO SEAL 200 combines high breathability with puncture resistance for long-term reliability.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Recommendations for installation

-

Environmental Product Declaration (EPD)

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 200 g/m² | 0.66 oz/ft² |

| Thickness | EN 1849-2 | 0,7 mm | 28 mil |

| Water vapour transmission (Sd) | EN 1931 | 0,08 m | 43.706 US perm |

| Tensile strength MD/CD | EN 12311-1 | 300 / 220 N/50mm | 34 / 25 lbf/in |

| Elongation MD/CD | EN 12311-1 | 50 / 70 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | 260 / 340 N | 58 / 76 lbf |

| Watertightness | EN 1928 | class W1 | - |

| Resistance to temperature | - | -40 / 120 °C | -40 / 248 °F |

| Reaction to fire | EN 13501-1 | class E | - |

| Resistance to penetration of air | EN 12114 | < 0,02 m³/(m²·h·50Pa) | < 0.001 cfm/ft² at 50Pa |

| Thermal conductivity (λ) | - | 0,04 W/(m·K) | 0.02 BTU/(h·ft·°F) |

| Specific heat | - | 1800 J/(kg·K) | - |

| Density | - | ca. 285 kg/m³ | - |

| Water vapour resistance factor (μ) | - | ca. 114 | - |

| UV stability | - | 1000h (8 months) | - |

| After artificial ageing - Tensile strength MD/CD | EN 1297 / EN 12311-1 | > 270 / 200 N/50mm | > 31 / 23 lb/in |

| After artificial ageing - elongation | EN 1297 / EN 12311-1 | > 25 / 35 % | - |

| Flexibility at low temperatures | EN 1109 | -40 °C | -40 °F |

| VOC | - | not relevant | - |

| Watertightness at 120°C after artificial ageing | EN 1297 / EN 1928 | class W1 | - |

Composition

| TOP LAYER | non-woven PP fabric |

|---|---|

| middle layer | breathable monolithic PU film |

| BOTTOM LAYER | non-woven PP fabric |

Specifications

TRASPIR EVO SEAL 200

Supply and installation of monolithic breathable membrane, resistant to screw or nail puncture, Type TRASPIR EVO SEAL 200.

Composition

From top layer to bottom layer:

non-woven PP fabric;

breathable monolithic PU film;

non-woven PP fabric.

Properties

Mass per unit area [g/m²]: 200

Thickness [mm]: 0,7

Water vapour transmission (Sd)[m]: 0,08

Tensile strength MD/CD [N/50 mm]: 300/220

Elongation MD/CD [%]: 50/70

Resistance to nail tearing MD/CD [N]: 260/340

Watertightness: class W1 (EN 1928)

Reaction to fire: class E (EN 13501-1)

Resistance to temperature [C°]: -40/120

UV stability: 1000h (8 months)

VOC [%]: not applicable

Standards and certifications

CE marked in accordance with EN 13859-1/2

LCA

EPD

AUS 4200.1 Class 4

Description

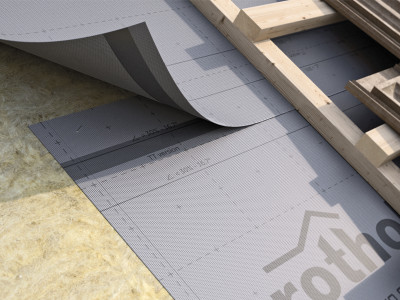

The application surface must be dry, free of dust and grease. Surface elements must be removed so that the membrane is not damaged during application.

The oversized TPU film ensures that the membrane remains waterproof even in the event of a screw or nail puncture without the need for additional products.

Recommended use: direct UV protection is guaranteed. Installation is therefore permitted on both the internal and external sides of the building envelope.

Installation: Unroll the membrane. If the version without double-sided adhesive strips is used, sealing must be carried out using tape such as: FLEXY BAND, FLEXY BAND UV, SPEEDY BAND, or EASY BAND.

Ensure that the overlap between the membranes is at least 15 cm to achieve an optimal seal.

Further details regarding installation can be found in the specific instructions provided by the supplier.