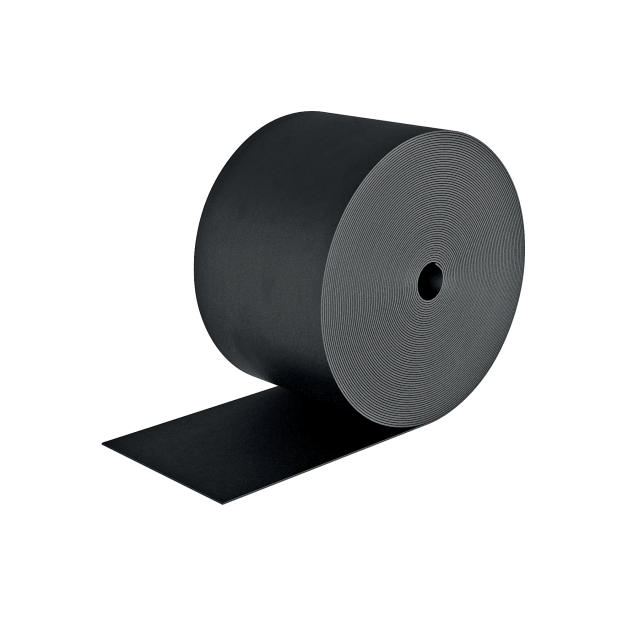

TRASPIR WELD EVO 360

TRASPIR WELD EVO 360 is a weldable monolithic breathable membrane for waterproofing timber roofs. It offers excellent UV stability and consists of a pair of monolithic thermoplastic polyurethane films coated on a polyester reinforcement.

Description

TRASPIR WELD EVO 360, THE MONOLITHIC MEMBRANE THAT CAN BE HEAT OR CHEMICALLY WELDED

The monolithic structure of the TRASPIR WELD EVO 360 membrane guarantees excellent durability over time, due to the special polymers used. The double polyurethane membrane offers perfect welding on all overlapping and joints, for total waterproofing.

With the possibility of both hot and chemical welding, it makes it possible to create a single solid protective layer that is highly reliable, returning continuity to the various layers. Thanks to its mass per unit area, it can also be effectively installed on roofs with pitches greater than 5°. Also available in a 3-metre version for faster installation.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Xml-File WUFI

-

Environmental Product Declaration (EPD)

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 360 g/m² | 1.18 oz/ft² |

| Thickness | EN 1849-2 | 1 mm | 39 mil |

| Water vapour transmission (Sd) | EN 1931 | 0,2 m | 17.483 US perm |

| Tensile strength MD/CD | EN 12311-1 | 420 / 490 N/50mm | 48 / 56 lbf/in |

| Elongation MD/CD | EN 12311-1 | 50 / 65 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | 310 / 280 N | 70 / 63 lbf |

| Watertightness | EN 1928 | class W1 | - |

| Resistance to temperature | - | -40 / 120 °C | -40 / 248 °F |

| Reaction to fire | EN 13501-1 | class E | - |

| Resistance to penetration of air | EN 12114 | 0,02 m³/(m²·h·50Pa) | 0.001 cfm/ft² at 50Pa |

| Thermal conductivity (λ) | - | 0,4 W/(m·K) | 0.23 BTU/(h·ft·°F) |

| Specific heat | - | 1800 J/(kg·K) | - |

| Density | - | ca. 360 kg/m³ | - |

| Water vapour resistance factor (μ) | - | ca. 200 | - |

| Joint strength | EN 12317-2 | > 490 / N/50mm | > 55.959442 / lb/in |

Composition

| TOP LAYER | breathable monolithic PU film |

|---|---|

| middle layer | PL fabric |

| BOTTOM LAYER | breathable monolithic PU film |

Specifications

TRASPIR WELD EVO 360

Supply and installation of weldable monolithic breathable membrane, like TRASPIR WELD EVO 360.

Composition

From top layer to bottom layer:

-

breathable monolithic PU film;

-

PL fabric;

-

breathable monolithic PU film.

Properties

-

Mass per unit area [g/m²]: 360

-

Thickness [mm]: 1

-

Water vapour transmission (Sd)[m]: 0,2

-

Tensile strength MD/CD [N/50 mm]: 420/490

-

Elongation MD/CD [%]: 50/65

-

Resistance to nail tearing MD/CD [N]: 310/280

-

Watertightness: class W1 (EN 1928)

-

Reaction to fire: class E (EN 13501-1)

-

Resistance to temperature [C°]: -40/120

-

UV stability: 1000h (8 months)

Standards and certifications

-

CE marked in accordance with EN 13859-1

-

LCA

-

EPD

-

AUS 4200.1 Class 3

Description

The application surface must be dry, free of dust and grease. Surface elements must be removed so that the membrane is not damaged during application.

The membrane allows the two functional TPU films to be sealed together on the outer edges, either with hot air or chemically, thus preventing humidity absorption.

Recommended use: direct UV protection is guaranteed. On roof, installation is permitted on both the internal and external sides of the building envelope; on walls, installation is permitted only on the internal side of the building envelope.

Installation: Unroll the membrane and seal using one of the two available methods: with hot air using a heat gun, or with adhesive, such as WELDING LIQUID.

Ensure that the overlap between the membranes is at least 15 cm to achieve an optimal seal.

To ensure correct and professional installation, the use of a nail sealing point is required.

Further details regarding installation can be found in the specific instructions provided by the supplier.