BYTUM LIQUID | REINFORCEMENT

Product made of distilled bitumen with elastoplastomeric polymer, with cold flexibility down to -15°C and resistance to heat up to 100°C.

Suitable for outdoor waterproofing using a specific product depending on the required technical solution.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

Technical Data BYTUM LIQUID

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Classification (1 ) | EN 1504-2 | C PI-MC-IR | - |

| Classification (2 ) | EN 14891 | DM O1 | - |

| Colour (wet/dry) | - | black/grey | - |

| Density | ISO 2811-1 | ca. 1,5 kg/L | ca. 12.52 lb/gal |

| Maximum application thickness | - | 3 mm | 118.11024 mil |

| Dry residue | ISO 3251 | ca. 77 % | - |

| Material yield per 1 mm thickness | - | 1,5 kg/m² | - |

| Water vapour transmission (Sd) (3 ) | EN ISO 7783 | classe I: < 5 m | - |

| Elongation at failure | EN ISO 37 | 200 % | - |

| Elongation with BYTUM REINFORCEMENT | EN 12311-1 | 80 | - |

| Reaction to fire | EN 13501-1 | class E | - |

| Thermal conductivity (λ) | - | 0,2 W/(m·K) | 0.12 BTU/(h·ft²·°F) |

| Crack bridging ability | EN 1602-7 | ≥ 10 mm | ≥ 394 mil |

| Crack bridging with BYTUM REINFORCEMENT | EN 1602-7 | > 10 mm | > 394 mil |

| Static load resistance Met.A/Met.B | EN 12730 | - | - |

| Static load resistance Met.A/Met.B | EN 12730 | - | - |

| Impact resistance Met.A/Met.B | EN 12691 | - | - |

| Impact resistance Met.A/Met.B | EN 12691 | - | - |

| Specific heat | - | 1500 J/(kg·K) | - |

| Flexibility at low temperatures | EN 1109 | -10 °C | 14 °F |

| Resistance to temperature | - | -30 / 80 °C | -22 / 176 °F |

| Application temperature (ambient and support) | - | 5 / 35 °C | 41 / 95 °F |

| Time required for application of each layer on the previous one 23 °C / 50% RH (4 ) | - | 48 hours | - |

| Time required for complete hardening 23 °C / 50% RH (4 ) | - | 48 hours | - |

| Storage temperature | - | ≥ 5 / °C | ≥ 41 / °F |

| Direct traction adhesion on timber/metal | EN 1542 | 1,7 N/mm² | 247 lbf/in² |

| Dynamic viscosity | EN ISO 3219 | 65000 Pa·s | - |

| Water permeability (W) | EN 1062-3 | 0,1 kg/(m²·h⁰’⁵) | - |

| Impact resistance | EN 12691 | - | - |

| Tensile adhesion after immersion in water | EN 14891 | > 0,5 N/mm² | > 73 psi |

| Tensile adhesion after thermal ageing | EN 14891 | > 0,5 N/mm² | > 73 psi |

| Tensile adhesion after freeze-thaw cycles | EN 14891 | > 0,5 N/mm² | > 73 psi |

| Tensile adhesion after contact with lime water | EN 14891 | > 0,5 N/mm² | > 73 psi |

| Watertightness | EN 14891 | - | - |

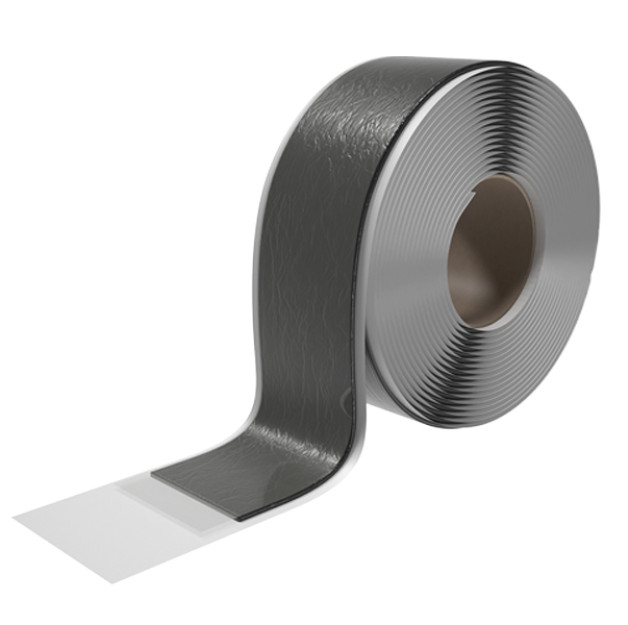

Technical Data BYTUM REINFORCEMENT

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 100 g/m² | 0.33 oz/ft² |

| Thickness | - | 0,5 mm | 20 mil |

Composition BYTUM REINFORCEMENT

| polyester reinforcing grid |

Specifications

BYTUM LIQUID | REINFORCEMENT

Supply and installation of a spreadable waterproofing sheath/reinforcing layer, Type BYTUM LIQUID | REINFORCEMENT.

Composition - REINFORCEMENT

- non-woven PL fabric

Properties

-

Density [kg/L]: approx. 1,5

-

Maximum applicable thickness (in two layers) [mm]: 3

-

Time required for application of each layer on the previous one 23 °C/50% RH: 24 h

-

Time required for drying 23 °C/50% RH: 48 h

-

Resistance to temperature [C°]: -30/+80

-

Application temperature (product, ambient and support) [°C]: +5/+35

-

Reaction to fire: class E (EN 13501-1)

-

Material yield per 1 mm thickness [kg/m2]: 1,5

-

Water vapour transmission (Sd)[m]: class I: < 5 m

-

Storage temperature [C°]: ≥ +5

Standards and certifications

CE marked in accordance with EN 1504-2, EN 14891, EN 15814

Application surface

The application surface must be dry, free of dust and grease, and not be anti-adhesive.

Multipurpose waterproof product made from bitumen, selected elastomeric resins and special additives.

Thanks to its unique composition, it is both paintable and suitable for use as an underfloor waterproof solution. It provides long-lasting performance with excellent resistance to water stagnation, weathering and UV rays.

Recommended use

Suitable for external waterproofing applications, with specific product variants depending on the required technical solution.

When combined with a synthetic reinforcing fabric, such as REINFORCEMENT, the sheath is also suitable for vertical applications, highly stressed substrates, and surfaces larger than 10 m².

Installation

Apply the product using a brush. If required, place the reinforcing membrane onto the freshly applied layer, ensuring full and proper adhesion. Allow to dry completely.

Further details regarding installation can be found in the specific instructions provided by the supplier.