EXPAND BAND

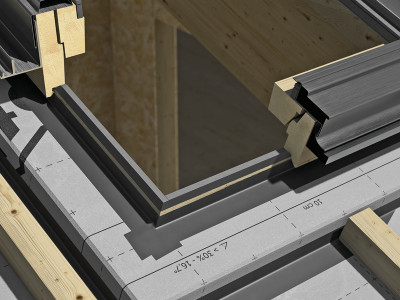

EXPAND BAND expanding tape provides permanent elastic expansion that remains unchanged over time, ensuring protection from water, dust and wind. Also available in EVO version without separating layer which, with its special film, keeps its shape as long as it is rolled up.

EXPAND BAND self-expanding tape, performance and durability over time

Description

EXPAND BAND self-expanding tape consists of a modified polyurethane foam that has passed the most stringent tests on harmful emissions, ensuring safe installation even indoors.

The EVO version not only reduces waste and installation time because it has no separating layer, but also has a special film that keeps its shape without self-expanding as long as it is rolled up. The self-expanding tape is supplied with a plastic core to prevent water and moisture absorption during construction, which could cause unwanted swelling.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Fire test report

-

EMICODE Certificate

EXPAND BAND

| CODE | B

[mm]

|

measures

[mm]

|

L

[m]

|

B

[in]

|

L

[ft]

|

pcs. |

|---|---|---|---|---|---|---|

| EXPAND1014 | 10 | s: 1-4 | 13 | 0.4 | 43 | 48 |

| EXPAND1514 | 15 | s: 1-4 | 13 | 0.6 | 43 | 32 |

| EXPAND1549 | 15 | s: 4-9 | 8 | 0.6 | 26 | 32 |

| EXPAND15615 | 15 | s: 6-15 | 6 | 0.6 | 20 | 32 |

| EXPAND20920 | 20 | s: 9-20 | 4 | 0.8 | 13 | 24 |

| EXPAND40615 | 40 | s: 6-15 | 8 | 1.6 | 26 | 12 |

| EXPAND60615 | 60 | s: 6-15 | 8 | 2.4 | 26 | 8 |

EXPAND BAND EVO

| CODE | B

[mm]

|

measures

[mm]

|

L

[m]

|

B

[in]

|

L

[ft]

|

pcs. |

|---|---|---|---|---|---|---|

| EXPANDEVO1514 | 15 | 1-4 | 13 | 0.6 | 43 | 32 |

Technical Data EXPAND BAND

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Classification (1 ) | DIN 18542 | BG1 | - |

| Airtightness | DIN 18542 | conforme ai requisiti BG1 | - |

| Resistance to penetration of air | EN 12114 | ≤ 1 m³/(m²·h·50Pa) | ≤ 0.055 cfm/ft² at 50Pa |

| Resistance to heavy rain | EN 1027 | ≥ 600 Pa | - |

| Light and humidity resistance | DIN 18542 | conforme ai requisiti BG1 | - |

| Compatibility with building materials | DIN 18542 | conforme ai requisiti BG1 | - |

| Water vapour transmission (Sd) | DIN 18542 | conforme ai requisiti BG1 | - |

| Water vapour transmission (Sd) | EN 1931 / EN ISO 12572 | < 0,5 m | < 6.993 US perm |

| Reaction to fire | DIN 4102-1 | class B1 | - |

| Fire resistance rating on CLT joint* (2 ) | en 1366-4 | EI120 | - |

| Thermal conductivity (λ) | EN 12667 | ≤ 0,043 W/(m·K) | ≤ 0.02 BTU/(h·ft·°F) |

| Resistance to temperature | - | -30 / 90 °C | -22 / 194 °F |

| Application temperature | - | ≥ 5 °C | ≥ 41 °F |

| Storage temperature | - | 1 / 20 °C | 34 / 68 °F |

Composition EXPAND BAND

| TOP LAYER | elastic polyurethane foam with additives |

|---|---|

| GLUE | - |

| RELEASE LINER | silicone coated paper |