FRONT BAND UV 210

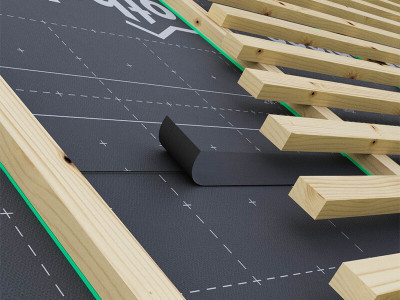

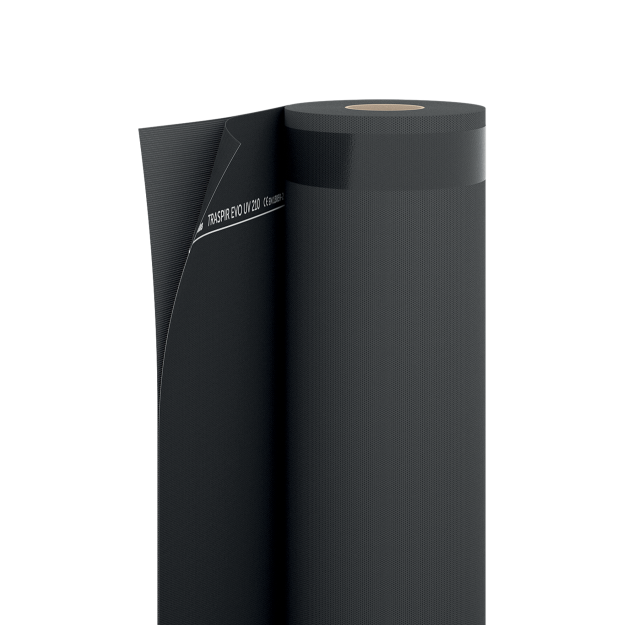

FRONT BAND UV 210 is the universal tape made of TRASPIR EVO UV 210 monolithic membrane that provides excellent aesthetic performance even in the most demanding architectural solutions.

Self-extinguishing tape classified B-s1,d0, that does not spread the flame in case of fire, contributing to the passive protection of the structure.

Description

FRONT BAND UV 210 IS THE FAÇADE SEALING SOLUTION THAT IS NOT AFFECTED BY THE SUN'S RAYS, NOT TODAY, NOT EVER.

The combination of FRONT BAND UV 210 universal tape with TRASPIR EVO UV 210 and TRASPIR EVO 300 membranes offers the first B-s1,d0 tested system available on the market, as well as ensuring the aesthetic homogeneity of the façade system.

Heat resistance reaches up to 100°C: the product carrier is made from a new generation monolithic membrane, that ensures high levels of thermal and UV stability.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

FRONT BAND UV 210

| CODE | B

[mm]

|

L

[m]

|

B

[in]

|

L

[ft]

|

pcs. |

|---|---|---|---|---|---|

| FRONTUV75 | 75 | 20 | 3 | 66 | 8 |

Composition

| SUPPORT | TRASPIR EVO UV 210 |

|---|---|

| GLUE | acrylic dispersion without solvents |

| RELEASE LINER | PP film |

Specifications

FRONT BAND UV 210

Supply and installation of universal single-sided tape with high UV resistance, type FRONT BAND UV 210.

Composition

From top layer to bottom layer:

– Carrier made of highly breathable monolithic UV-resistant membrane, type TRASPIR EVO UV 210;

-

acrylic dispersion without solvents;

-

PP film.

Properties

-

Thickness [mm]: 0,5

-

Adhesion strength on OSB at 90° after 10 minutes [N/10 mm]: 5,0

-

Adhesion strength on OSB at 180° after 10 minutes [N/10 mm]: 8,0

-

Adhesion strength (average) on membrane in PP after 24 hours [N/50 mm]: 40,0

-

Shear adhesion strength of the joint on membrane in PP after 24 hours [N/50 mm]: 145,0

-

Tensile strength MD/CD [N/50 mm]: 300/200

-

Elongation MD/CD [%]: 25/25

-

Water vapour transmission (Sd)[m]: 0,1

-

Watertightness: compliant

-

UV resistance without final coating: 10000h (>12 months)

-

Reaction to fire: class B-s1, d0 (EN 13501-1)

-

Application temperature [C°]: +5/+40

-

Resistance to temperature [C°]: -30/+100

-

Storage temperature [C°]: +5/+25

-

Solvents: no

Description

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

Recommended use: Suitable for application on various smooth building substrates, such as timber or OSB panels, without the need for additional surface treatment. If the tape is applied to brick or concrete surfaces, the use of a primer such as PRIMER SPRAY is recommended.

The complete list of approved application surfaces can be found in the specific instructions provided by the manufacturer.

Installation: Apply the tape with uniform pressure over the entire surface to ensure full contact with the support.

Once tape installation is complete, a pressure roller must be used to ensure perfect adhesion.