GROUND BAND

GROUND BAND is the self-adhesive and self-sealing bituminous membrane tested for protection against radon gas and methane gas, which are harmful to health in case of high concentration in indoor environments.

Practical and fast installation, no flames are required, minimising risks for the wood.

Description

GROUND BAND, THE BITUMINOUS MEMBRANE FOR WATERPROOFING AND RADON PROTECTION OF FOUNDATIONS

The self-adhesive bituminous GROUND BAND membrane installation is effective from +5 °C to +30 °C, thanks to the special elastoplastomeric bituminous compound; the sheath remains flexible down to -30 °C.

All versions are supplied with the liner pre-cut to facilitate installation in corners or complex locations, but also over large areas to avoid excessive misalignment of the layers.

The special elastoplastomeric bituminous compound and the cross-laminated high-density polyethylene backing film make the membrane completely waterproof and resistant to punching shear.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Water vapour resistance factor (μ) | EN 1931 / EN ISO 12572 | ca. 90000 | - |

| Tensile strength MD/CD | EN 12311-1 | 215 / 220 N/50mm | 25 / 25 lbf/in |

| Elongation MD/CD | EN 12311-1 | 310 / 240 % | - |

| Impact resistance Met.A/Met.B | EN 12691 | 500 / 1000 mm | 19.7 / 39.4 in |

| Static load resistance Met.A/Met.B | EN 12730 | 10 / 15 kg | 353 / 529 oz |

| Resistance to nail tearing MD/CD | EN 12310-1 | 135 / 135 N | 30 / 30 lbf |

| Watertightness | EN 1928 | ≥ 60 kPa | - |

| Watertightness after artificial ageing | EN 1296-EN 1928 | compliant | - |

| Joint separation resistance MD/CD | EN 12316-1 | 100 N/50mm | 11.42 lbf/in |

| Maximum tensile force MD/CD | EN 12317-1 | 350 / 350 N/50mm | 39.97 / 39.97 lbf/in |

| Water absorption | ASTM D 570 | 0,09 % | - |

| Resistance to hydrostatic pressure (24h) | DIN 52123 | > 6 bar | - |

| Reaction to fire | EN 13501-1 | class E | - |

| Initial Tack | ASTM D2979 | 75 N | 16.9 lbf |

| Adhesion strength on timber | ASTM D1000 | 12,5 N/10mm | 7.14 lbf/in |

| Adhesion strength on concrete at 180° | ASTM D1000 | 165 N/mm | 942.22 lbf/in |

| Flexibility at low temperatures | EN 1109 | -30 °C | -22 °F |

| Resistance to temperature | - | 40 / 80 °C | 104 / 176 °F |

| Application temperature | - | -5 / 30 °C | 23 / 86 °F |

| Storage temperature (1 ) | - | 5 / 40 °C | 41 / 104 °F |

| Exposure to weather | - | 3 weeks | - |

| Radon permeability | SP Swedish Nat. Testing & Research Institute | 5,7e-12 m²/s | - |

| Methane permeability | metodo di prova CSI | < 5 cc/(m²·24h·atm) | - |

| VOC emissions | EN 16000 | 8 μg/m³ | - |

| Solvents | - | no | - |

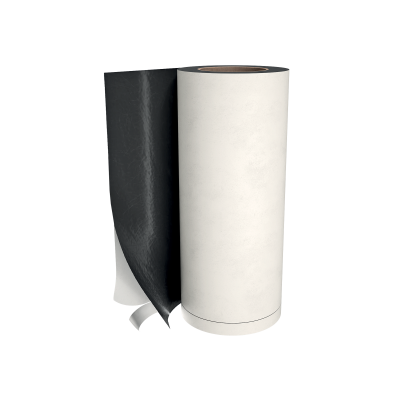

Composition

| SUPPORT | high density cross-laminated PE film |

|---|---|

| GLUE | black adhesive bituminous compound |

| RELEASE LINER | silicone coated paper |

Specifications

GROUND BAND

Supply and installation of self-adhesive bituminous membrane, type GROUND BAND.

Composition

From top layer to bottom layer:

-

silicone coated paper;

-

black adhesive bituminous compound;

-

high density cross-laminated PE film.

Properties

-

Tensile strength MD/CD [N/50 mm]: 215/220

-

Elongation MD/CD [%]: 310/240

-

Resistance to tearing MD/CD [N]: 135/135

-

Watertightness: comply with (EN 1928)

-

Joint separation resistance MD/CD [N/50 mm]: 100

-

Joint tensile strength MD/CD [N/50 mm]: 350/350

-

Water absorption [%]: 0,09

-

Reaction to fire: class E (EN 13501-1)

-

Resistance to temperature [C°]: -40/+80

-

Application temperature [C°]: -5/+30

-

Storage temperature [°C]: +5/+40

-

Exposure to weather: 3 weeks

-

Radon permeability [m2/s]: 5,7·10^-12

-

Methane permeability [cc/m2·24·atm]: < 5

-

VOC [μg/m3]: 8

-

Solvents: no

Standards and certifications

CE marked in accordance with EN 13969 - EN 14967 - EN 13707

Description

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

Recommended use

Suitable for application on various smooth building substrates, such as timber or OSB panels, without the need for additional surface treatment. If the tape is applied to brick or concrete surfaces, the use of a primer such as BYTUM PRIMER is recommended.

The complete list of approved application surfaces can be found in the specific instructions provided by the manufacturer. The product is tested for protection against radon and methane gas.

The special elastoplastomeric bituminous compound and the cross-laminated high-density polyethylene backing film make the membrane completely waterproof and resistant to punching shear.

It does not require the use of flame, minimising risks to timber.

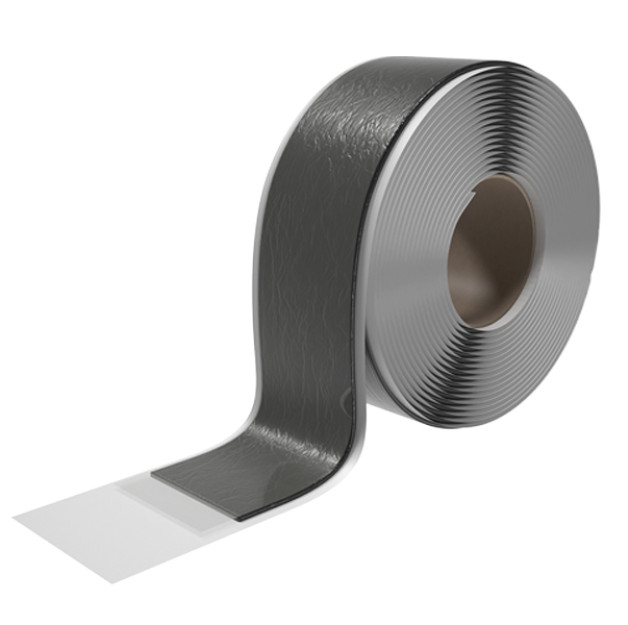

Installation

Unroll the membrane and partly remove the protective release film from the adhesive side to facilitate installation on both sharp-edged and flat surfaces. Continue by fastening each layer to the substrate with a mechanical fastening device to ensure installation stability. The sealing is completed by removing the remaining liner and adhering the tape to the support.

Once tape installation is complete, a pressure roller or a hot air gun such as the HOT GUN must be used to ensure perfect adhesion.

Further details regarding installation can be found in the specific instructions provided by the supplier.