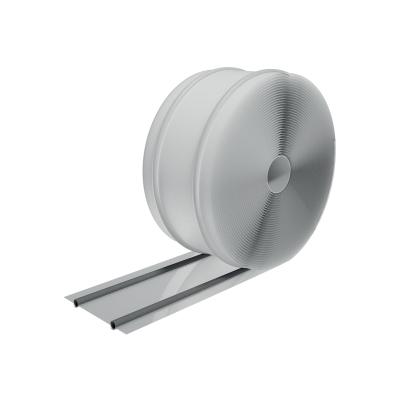

LEVEL BAND

The LEVEL BAND sealing wall barrier for substrates effectively resists humidity due to capillary action, while offering excellent resistance to water, air and wind.

Available in three sizes and it is ideal both as a wall barrier and to seal vertical wall-wall joints.

Description

LEVEL BAND, the sealing wall barrier that eliminates the problem of rising damp

Thanks to its soft and elastic polyethylene profile, the LEVEL BAND substrate sealant wall barrier can also be installed in complex shapes and angles.

The choice of materials and optimisation in production results in a solution that offers a good balance between performance and cost.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Declaration of performance (DOP)

LEVEL BAND

| CODE | B

[mm]

|

s

[mm]

|

L

[m]

|

B

[in]

|

s

[mil]

|

L

[ft]

|

pcs. |

|---|---|---|---|---|---|---|---|

| LEVEL085 | 85 | 0.17 | 25 | 3.3 | 7 | 82 | 2 |

| LEVEL125 | 125 | 0.17 | 25 | 4.9 | 7 | 82 | 2 |

| LEVEL350 | 350 | 0.17 | 25 | 13.8 | 7 | 82 | 2 |

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Tensile strength MD/CD | EN 12311-2 | ≥ 20 / 20 N/mm² | ≥ 0 / 0 lbf/mil² |

| Elongation MD/CD | EN 12311-2 | ≥ 550 / 600 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | ≥ 120 / 120 N | ≥ 27 / 27 lbf |

| Impact resistance | EN 12691 | > 500 mm | > 19.68504 in |

| Watertightness after artificial ageing | EN 1296-EN 1928 | compliant | - |

| Watertightness | EN 1928 | compliant | - |

| Alkaline water vapour resistance | EN 1847 / EN 12311-2 | compliant | - |

| Flexibility at low temperatures | EN 1109 | < -30 °C | < -22 °F |

| Resistance to temperature | - | 40 / 90 °C | 104 / 194 °F |

| Storage temperature (1 ) | - | 10 / 25 °C | 50 / 77 °F |

| Flexibility at low temperatures | EN 495-5 | -30 °C | -22 °F |

Composition

| - | |

| SUPPORT | PE film |

Specifications

LEVEL BAND

Supply and installation of sealing wall barrier for substrates, Type LEVEL BAND.

Properties

-

Tensile strength MD/CD [ N/mm2]: ≥ 20/≥ 20

-

Elongation MD/CD [%]: ≥ 550/≥ 600

-

Resistance to nail tearing MD/CD [N/mm2]: ≥ 120/≥ 120

-

Impact resistance [mm]: > 500

-

Watertightness: comply with (EN 1928)

-

Resistance to temperature [°C]: -40/+90

-

Storage temperature [C°]: +10/+25

Standards and certifications

CE marked in accordance with EN 13984

Description

The application surface must be dry, free of dust and grease. Surface elements must be removed so that the membrane is not damaged during application.

Recommended use

Suitable for application on various smooth building substrates, such as timber or OSB panels, without the need for additional surface treatment.

The complete list of permitted installation surfaces can be found in the specific instructions provided by the supplier. Suitable both as a wall barrier and for sealing vertical wall-to-wall joints.

It effectively blocks humidity due to capillary action, while offering excellent resistance to water, air and wind.

The soft and elastic polyethylene profile allows it to be installed even in complex shapes and angles

Installation

The tape must be applied by unrolling it along the element and fastening it with staples.