PROTECT

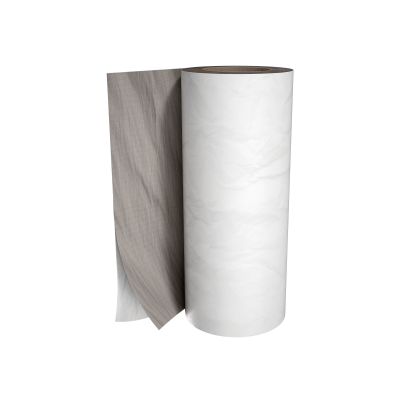

PROTECT is the self-adhesive butyl band that, thanks to the special mixture, guarantees excellent adhesion and deformation capacities, compensating for the natural movement of the timber.

Butyl provides excellent adhesion to substrates even in harsh environmental conditions, for top adhesion and workability even at low temperatures.

Description

PROTECT, THE SELF-ADHESIVE, PLASTERABLE BUTYL BAND FOR YOUR PROJECTS

The PROTECT sheath is durable and thermally stable.

The non-woven polypropylene fabric means the support can be plastered, offering greater versatility of use.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Fire test report

Technical Data PROTECT

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Tensile strength MD/CD | EN 12311-1 | 115 / 100 N/50mm | 13 / 11 lbf/in |

| Elongation MD/CD | EN 12311-1 | 100 / 100 % | - |

| Adhesion strength on steel at 180° | ASTM D1000 | 22 N/10mm | 12.6 lbf/in |

| Initial Tack | ASTM D2979 | - | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | ≥ 130 / 125 N | ≥ 29 / 28 lbf |

| Joint separation resistance MD/CD | EN 12316-1 | ≥ 20 N/50mm | ≥ 2.28 lbf/in |

| Maximum tensile force MD/CD | EN 12317-1 | - | - |

| Adhesion of C2E cementitious glue on the product | EN 12004 / EN 1348 | 0,9 N/mm² | 131 lbf/in² |

| Vertical sliding | ISO 7390 | 0 mm | - |

| Reaction to fire | EN 13501-1 | class E | - |

| Water vapour resistance factor (μ) | - | ca. 26176 | - |

| Watertightness | EN 1928 | compliant | - |

| VOC emissions | EN 16000 | 30 μg/m³ | - |

| French VOC classification | ISO 16000 | A+ | - |

| Resistance to temperature | - | -40 / 120 °C | -40 / 248 °F |

| Application temperature | - | 0 / 45 °C | 32 / 113 °F |

| Storage temperature | - | 0 / 50 °C | 32 / 122 °F |

| Exposure to weather | - | 4 weeks | - |

| VOC | - | very low emissions | - |

| Fire resistance rating on CLT joint* (1 ) | en 1366-4 | EI90 | - |

Composition PROTECT

| SUPPORT | non-woven PP fabric |

|---|---|

| GLUE | grey adhesive butyl compound |

| RELEASE LINER | PP film |

Specifications

PROTECT

Supply and installation of self-adhesive butyl band that can be plastered, type PROTECT.

Composition

From top layer to bottom layer:

-

PP film;

-

grey adhesive butyl compound;

-

non-woven PP fabric.

Properties

-

Tensile strength MD/CD [N/50 mm]: 115/100

-

Elongation MD/CD [%]: 100/100

-

Resistance to nail tearing MD/CD [N]: ≥ 130/≥ 125

-

Watertightness: comply with (EN 1928)

-

Reaction to fire: class E (EN 13501-1)

-

Resistance to temperature [C°]: -40/+120

-

Application temperature [°C]: +0/+45

-

Storage temperature [°C]: +0/+50

-

Exposure to weather: 4 weeks

-

French VOC classification: A+

-

VOC emissions: very low

Standards and certifications

- CE marked in accordance with EN 13956

Description

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

Recommended use: Installation is permitted on both the internal and external sides of the building envelope.

The non-woven polypropylene fabric means the support can be plastered, offering greater versatility of use.

The butyl guarantees excellent adhesion to the supports also under difficult environmental conditions.

Installation:

Unroll the membrane over the surface, progressively remove the release film from the adhesive, and press the membrane firmly to ensure proper adhesion.

Once membrane installation is complete, a pressure roller must be used to ensure perfect adhesion.

In cold climates, the adhesive side of the membrane can be preheated using a hot air gun, such as HOT GUN, to achieve optimal bonding