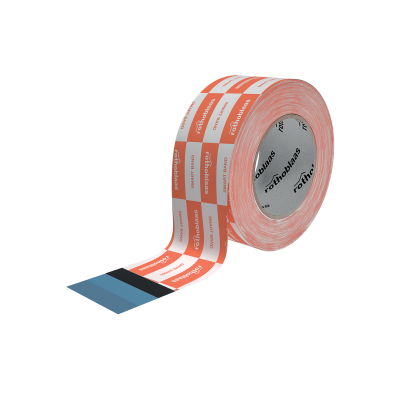

SMART BAND

SMART BAND universal tape with separable liner meets all the requirements to be classified as a tape for sealing external doors or windows, ensuring maximum safety even in case of stagnating water.

Extremely versatile, it can be used for a wide range of applications.

Description

SMART BAND, THE HIGHLY DEFORMABLE UNIVERSAL TAPE WITH EASY SPLITTING LINER

The SMART BAND universal single-sided tape has a unique separating film which, thanks to a special treatment, can be divided at any point without pre-cutting, thus adapting to any installation requirement.

The special composition of the support makes the tape particularly resistant to tearing and mechanical stress, thanks to its high deformability.

Storage is made easier thanks to the easy splitting liner, which means that only a few sizes can be stored to meet any construction requirement.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

SMART BAND

| CODE | B

[mm]

|

L

[m]

|

B

[in]

|

L

[ft]

|

pcs. |

|---|---|---|---|---|---|

| SMART60 | 60 | 25 | 2.4 | 82 | 10 |

| SMART75 | 75 | 25 | 3 | 82 | 8 |

| SMART100 | 100 | 25 | 3.9 | 82 | 6 |

| SMART150 | 150 | 25 | 5.9 | 82 | 4 |

| SMART225 | 225 | 25 | 8.9 | 82 | 2 |

| SMART300 | 300 | 25 | 11.8 | 82 | 2 |

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Thickness | - | 0,24 mm | 9 mil |

| Tensile strength | ASTM D1000 | 30 N/10mm | 17.13 lbf/in |

| Elongation at failure | ASTM D1000 | ≥ 400 % | - |

| Resistance to heavy rain | - | compliant | - |

| Application temperature | - | -10 / 40 °C | 14 / 104 °F |

| Resistance to temperature | - | -30 / 80 °C | -22 / 176 °F |

| Storage temperature | - | 5 / 30 °C | 41 / 86 °F |

| Adhesion strength on steel at 90° | AFERA 5001 | ≥ 12 N/25mm | ≥ 2.74 lbf/in |

| Resistance to heavy rain | TU Berlin | npd | - |

| Solvents | - | no | - |

| Adhesion strength on OSB at 180° after 10 minutes | EN ISO 29862 | 7 N/10mm | 4 lbf/in |

| Adhesion strength on OSB at 90° after 10 minutes | EN ISO 29862 | 3,5 N/10mm | 2 lbf/in |

| Adhesion strength (average) on membrane in PP after 24 hours | EN 12316-2 | 26 N/50mm | 3 lbf/in |

| Shear adhesion strength of the joint on membrane in PP after 24 hours (1 ) | EN 12317-2 | 55 N/50mm | 6.3 lbf/in |

| Watertightness | - | compliant | - |

| Exposure to weather | - | 12 month | - |

Composition

| SUPPORT | PE special film |

|---|---|

| SUPPORT | UV-stabilised PE film |

| GLUE | solvent-free UV-crosslinked acrylic |

| RELEASE LINER | PP film with easy splitting |

Specifications

SMART BAND

Supply and installation of universal single-sided tape with separable liner, Type SMART BAND.

Composition

From top layer to bottom layer:

-

PE special film;

-

UV-stabilised PE film;

-

acrylic dispersion without solvents;

-

PP film with easy splitting.

Properties

-

Thickness [mm]: 0,24

-

Adhesion strength on OSB at 90° after 10 minutes [N/10 mm]: 3,5

-

Adhesion strength on OSB at 180° after 10 minutes [N/10 mm]: 7,0

-

Adhesion strength (average) on membrane in PP after 24 hours [N/50 mm]: 26,0

-

Shear adhesion strength of the joint on membrane in PP after 24 hours [N/50 mm]: 55,0

-

Tensile strength [N/10 mm]: 30

-Elongation at failure [%]: ≥ 400

-

Watertightness: class W1 (EN 1928)

-

Exposure to weather: 12 months

-

Application temperature [°C]: -10/+40

-

Resistance to temperature [C°]: -30/+80

-

Storage temperature [C°]: +5/+30

-

Solvents: no

Description

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

The special composition of the UV-stabilised support makes the tape particularly resistant to tearing and mechanical stress, due to its high deformability.

The product has a unique separating film which, thanks to a special treatment, can be divided at any point without pre-cutting, thus adapting to any installation requirement.

Recommended use: Suitable for application on various smooth building substrates, such as timber or OSB panels, without the need for additional surface treatment. If the tape is applied to brick or concrete surfaces, the use of a primer such as PRIMER SPRAY is recommended.

The complete list of approved application surfaces can be found in the specific instructions provided by the manufacturer.

It meets all the requirements to be classified as a tape for sealing external doors or windows, ensuring maximum safety even in case of stagnant water, heavy rain and perforations

Installation: Apply the tape with uniform pressure over the entire surface to ensure full contact with the support.

Once tape installation is complete, a pressure roller must be used to ensure perfect adhesion.

Further details regarding installation can be found in the specific instructions provided by the supplier