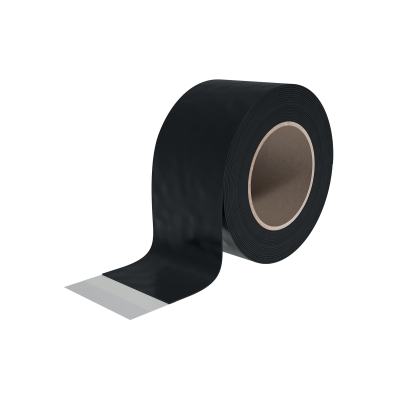

TERRA BAND UV

The TERRA BAND UV adhesive butyl tape is ideal for protecting joists from water and UV rays.

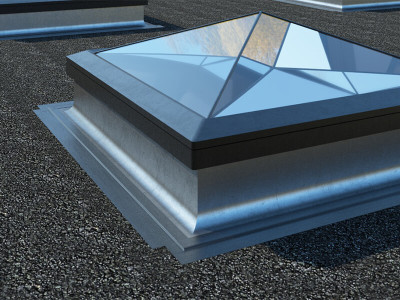

Can be used for both patios and for cladding façades, protecting and extending the life of the wooden joists.

The aluminised support guarantees unlimited resistance to UV radiation that can penetrate between open joints of patios and façades.

Description

TERRA BAND UV BUTYL TAPE, THE ADHESIVE TAPE WITH UNLIMITED UV RESISTANCE

The TERRA BAND UV butyl adhesive tape is soft and easy to work with. Its special butyl mix closes over the perforations and remains perfectly watertight.

The modified butyl formulation ensures excellent durability even when subjected to thermal and UV stress.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

TERRA BAND UV

| CODE | B

[mm]

|

s

[mm]

|

L

[m]

|

B

[in]

|

s

[mil]

|

L

[ft]

|

pcs. |

|---|---|---|---|---|---|---|---|

| TERRAUV75 | 75 | 0.8 | 10 | 3 | 31 | 33 | 8 |

| TERRAUV100 | 100 | 0.8 | 10 | 3.9 | 31 | 33 | 6 |

| TERRAUV200 | 200 | 0.8 | 10 | 7.9 | 31 | 33 | 4 |

| TERRAUV400 | 400 | 0.8 | 10 | 15.7 | 31 | 33 | 2 |

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Thickness | - | 0,8 mm | 31 mil |

| Initial Tack +23/+5 °C | ASTM D2979 | 7,2 / 13 N | 1.6 / 2.9 lbf |

| Adhesion strength on steel at 180° | ASTM D1000 | 20 N/10mm | 11.4 lbf/in |

| Vertical sliding | ISO 7390 | 0 mm | - |

| Tensile strength MD/CD | EN 12311-1 | 185 / 200 N/50mm | 21 / 23 lbf/in |

| Elongation MD/CD | EN 12311-1 | 10 / 20 % | - |

| Water vapour resistance factor (μ) | EN 1931 / EN ISO 12572 | 2720000 | - |

| Reaction to fire | EN 13501-1 | class E | - |

| Resistance to temperature | - | -40 / 100 °C | -40 / 212 °F |

| Application temperature (1 ) | - | 0 / 40 °C | 32 / 104 °F |

| Watertightness | - | compliant | - |

| UV resistance | - | permanent | - |

| Storage temperature | - | 5 / 40 °C | 41 / 104 °F |

| French VOC classification | ISO 16000 | A+ | - |

| VOC emissions | EN 16516 | very low | - |

| Solvents | - | no | - |

Composition

| SUPPORT | - |

|---|---|

| GLUE | grey adhesive butyl compound |

| RELEASE LINER | PE film |

Specifications

TERRA BAND UV

Supply and installation of universal butyl adhesive tape, Type TERRA BAND UV.

Composition

From top layer to bottom layer:

-

UV-stable anthracite-coloured reinforced aluminium film:

-

grey adhesive butyl compound;

-

PE film.

Properties

-

Thickness [mm]: 8

-

Tensile strength MD/CD [N/50 mm]: 185/200

-

Elongation MD/CD [%]: 10/20

-

Reaction to fire: class E (EN 13501-1)

-

Resistance to temperature [C°]: -40/+100

-

Application temperature [°C]: +0/+40

-

Watertightness: compliant

-

Resistant to UV rays: permanent

-

Storage temperature [°C]: +5/+40

-

French VOC classification: A+

-

VOC emissions: very low

-

Solvents: no

Application surface

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

Recommended use

Suitable for application on various smooth building substrates, such as timber or OSB panels, without the need for additional surface treatment. If the tape is applied to brick or concrete surfaces, the use of a primer such as BYTUM LIQUID is recommended.

Ideal for protecting battens from water and UV rays. Can be used for both patios and façades, protecting and extending the life of the wooden joists.

The reinforced aluminium backing and the butyl-based formulation ensure excellent durability, even under thermal stress conditions and continuous UV exposure.

Installation

The tape must be applied by exerting uniform pressure over the entire surface to ensure full contact with the substrate. The use of the dedicated roller is required to achieve proper installation.

Further details regarding installation can be found in the specific instructions provided by the supplier.