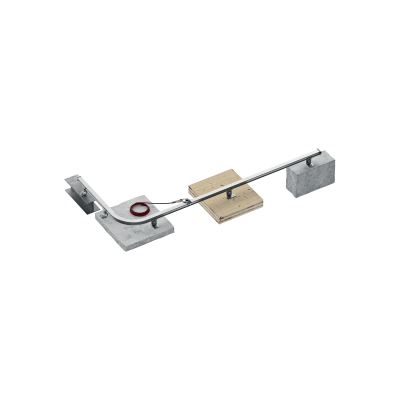

H-RAIL ON FLOOR

Construction work on rope and working at heights in general are easier and safer with this rail system for horizontal use. Compared to other safety systems for working at height, in fact, the rail fixed on the roof ensures a reduced footprint, guaranteeing minimal visual impact.

H-RAIL can be used for various applications. Assembly requires a limited number of fastening points with support spacing up to 6 m. Compared to the other H-RAIL models, H-RAIL ON FLOOR is installed on the roof covering, with the possibility of being raised to overcome any obstacles (H-RAIL+TOWER). Otherwise, H-RAIL ON WALL is installed on the wall, while H-RAIL OVERHEAD is installed below the supporting structure.

Description

Work on rope with H-RAIL ON FLOOR

There is often little room for manoeuvre in façade maintenance. When it comes to window cleaning, for example, there are few alternatives that guarantee the execution of work on rope and the safety of rope operators. Among these, the most common are BMUs (Building Maintenance Units or "baskets") and systems that integrate horizontal rails for rope access, such as H-RAIL. In contrast to BMUs, systems such as Rothoblaas H-RAIL are a discreet, elegant and quickly installed solution.

The advantages of H-RAIL in work on rope

In addition to improved aesthetics, small footprint and low weight, H-RAIL also has safety advantages. Whereas in BMUs, during work, operators have to lean out to reach the facade, risking swinging the basket, H-RAIL's rail allows suspended work, with the operator on the rope being harnessed and at the correct distance from the wall.

Also with regard to the speed of execution of work on rope, H-RAIL allows the presence of 4 operators at the same time on the same span, with a greater speed of execution of the work, even on inclined façades, with angles and narrow spaces.

Another advantage of a rigid system such as the H-RAIL rail system, this time in comparison to a traditional flexible lifeline, is the absence of falling cambers and the need to take this into account when calculating the vertical clearance.

Documents

-

Technical data sheets

-

Declaration of conformity

- Declaration of conformity Bulgarian

- Declaration of conformity Croatian

- Declaration of conformity Czech

- Declaration of conformity Danish

- Declaration of conformity Dutch

- Declaration of conformity English

- Declaration of conformity Estonian

- Declaration of conformity Finnish

- Declaration of conformity French

- Declaration of conformity German

- Declaration of conformity Greek

- Declaration of conformity Hungarian

- Declaration of conformity Italian

- Declaration of conformity Latvia

- Declaration of conformity Lithuanian

- Declaration of conformity Polish

- Declaration of conformity Portuguese

- Declaration of conformity Romanian

- Declaration of conformity Slovak

- Declaration of conformity Slovene

- Declaration of conformity Spanish

- Declaration of conformity Swedish

-

Safety regulations, instructions for installation and use

- Safety regulations, instructions for installation and use Arabian

- Safety regulations, instructions for installation and use Chinese

- Safety regulations, instructions for installation and use Croatian

- Safety regulations, instructions for installation and use Czech

- Safety regulations, instructions for installation and use Danish

- Safety regulations, instructions for installation and use Dutch

- Safety regulations, instructions for installation and use English

- Safety regulations, instructions for installation and use Estonian

- Safety regulations, instructions for installation and use Finnish

- Safety regulations, instructions for installation and use French

- Safety regulations, instructions for installation and use German

- Safety regulations, instructions for installation and use Greek

- Safety regulations, instructions for installation and use Icelandic

- Safety regulations, instructions for installation and use Italian

- Safety regulations, instructions for installation and use Japanese

- Safety regulations, instructions for installation and use Latvia

- Safety regulations, instructions for installation and use Lithuanian

- Safety regulations, instructions for installation and use Norwegian

- Safety regulations, instructions for installation and use Polish

- Safety regulations, instructions for installation and use Portuguese

- Safety regulations, instructions for installation and use Romanian

- Safety regulations, instructions for installation and use Russian

- Safety regulations, instructions for installation and use Slovak

- Safety regulations, instructions for installation and use Slovene

- Safety regulations, instructions for installation and use Spanish

- Safety regulations, instructions for installation and use Swedish

- Safety regulations, instructions for installation and use Turkish

-

File BIM.ifc

-

File BIM.rfa

-

Declaration of Installation and inspection

- Declaration of Installation and inspection Arabian

- Declaration of Installation and inspection Chinese

- Declaration of Installation and inspection Croatian

- Declaration of Installation and inspection Czech

- Declaration of Installation and inspection Danish

- Declaration of Installation and inspection Dutch

- Declaration of Installation and inspection English

- Declaration of Installation and inspection Estonian

- Declaration of Installation and inspection Finnish

- Declaration of Installation and inspection French

- Declaration of Installation and inspection German

- Declaration of Installation and inspection Greek

- Declaration of Installation and inspection Hungarian

- Declaration of Installation and inspection Icelandic

- Declaration of Installation and inspection Italian

- Declaration of Installation and inspection Japanese

- Declaration of Installation and inspection Latvia

- Declaration of Installation and inspection Lithuanian

- Declaration of Installation and inspection Norwegian

- Declaration of Installation and inspection Polish

- Declaration of Installation and inspection Portuguese

- Declaration of Installation and inspection Romanian

- Declaration of Installation and inspection Russian

- Declaration of Installation and inspection Slovak

- Declaration of Installation and inspection Slovene

- Declaration of Installation and inspection Spanish

- Declaration of Installation and inspection Swedish

- Declaration of Installation and inspection Turkish

-

Installation manual

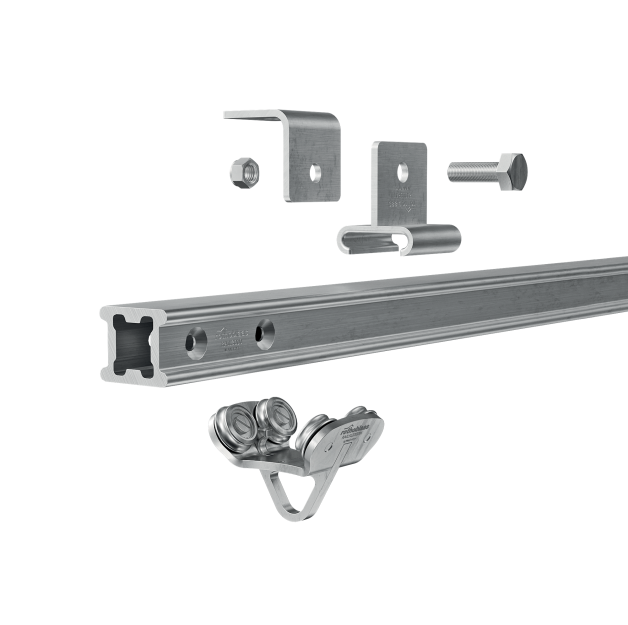

RAIL

| CODE | description | material | B

[mm]

|

H

[mm]

|

L

[mm]

|

pcs. |

|---|---|---|---|---|---|---|

| RAIL3000 | 3m aluminium rail | EN AW 6063 (T6) | 49 | 41 | 3000 | 1 |

| RAILC90 | 90° curved rail | EN AW 6063 (T6) | 475 | 41 | 475 | 1 |

| RAILC120 | 120° curved rail | EN AW 6063 (T6) | 336 | 41 | 538 | 1 |

| RAILC135 | 135° curved rail | EN AW 6063 (T6) | 257 | 41 | 536 | 1 |

| RAILC150 | 150° curved rail | EN AW 6063 (T6) | 178 | 41 | 512 | 1 |

SUPPORT

| CODE | description | pcs. |

|---|---|---|

| RAILBRAT | rail bracket | 1 |

| RAILBRAT12 | rail bracket | 1 |

| RAILBRATW | rail bracket | 1 |

| RAILBRAS | rail bracket | 1 |

| RAILBRAW | rail bracket | 1 |

TERMINAL ELEMENT

| CODE | description | material | B

[mm]

|

H

[mm]

|

L

[mm]

|

pcs. |

|---|---|---|---|---|---|---|

| RAILEND | rail terminal element | AISI 304 stainless steel grade 1.4301 | 84.5 | 48.6 | 55 | 1 |

| RAILENDA4 | rail terminal element | AISI 316 stainless steel grade 1.4401 | - | 48.6 | 55 | 1 |

| RAILENDOPEN | rail terminal element | AISI 304 stainless steel grade 1.4301 | 49 | 49 | 60 | 1 |

| RAILENDOPENA4 | rail terminal element | AISI 316 stainless steel grade 1.4401 | - | 49 | 60 | 1 |

JOINT

| CODE | description | material | B

[mm]

|

H

[mm]

|

L

[mm]

|

pcs. |

|---|---|---|---|---|---|---|

| RAILJUN | rail junction element | EN AW 6082 | 28.7 | 32.7 | 340 | 1 |

TOOL

| CODE | description | material | B

[mm]

|

H

[mm]

|

L

[mm]

|

pcs. |

|---|---|---|---|---|---|---|

| RAILJUNTOOL | rail tool | EN AW 6082 - 1.1191 (C45E) aluminium | 92 | 116 | 132 | 1 |

| RAILPLATE | rail id plate | - | - | 40 | 140 | 1 |

FASTENING

| CODE | description | material | pcs. |

|---|---|---|---|

| RAILOCKSCREW | lock screw | A2-70 | 250 |

| RAILSCREW | DIN 7991 A2-70 | A2-70 | 50 |

| RAILSCREWA4 | DIN 7991 A4-70 | A4-70 | 50 |

TARGAHORxy

| CODE | description | pcs. |

|---|---|---|

| TARGAHORIT | Label plate for PATROL and H-RAIL systems IT | 1 |

| TARGAHORDE | Label plate for PATROL and H-RAIL systems DE | 1 |

| TARGAHOREN | Label plate for PATROL and H-RAIL systems EN | 1 |

| TARGAHORES | Label plate for PATROL and H-RAIL systems ES | 1 |

| TARGAHORFR | Label plate for PATROL and H-RAIL systems FR | 1 |

| TARGAHORPT | Label plate for PATROL and H-RAIL systems PT | 1 |

| TARGAHORRU | Label plate for PATROL and H-RAIL systems RU | 1 |

| TARGAHORCS | Label plate for PATROL and H-RAIL systems CS | 1 |

| TARGAHORDA | Label plate for PATROL and H-RAIL systems DA | 1 |

| TARGAHOREL | Label plate for PATROL and H-RAIL systems EL | 1 |

| TARGAHORET | Label plate for PATROL and H-RAIL systems ET | 1 |

| TARGAHORFI | Label plate for PATROL and H-RAIL systems FI | 1 |

| TARGAHORHR | Label plate for PATROL and H-RAIL systems HR | 1 |

| TARGAHORHU | Label plate for PATROL and H-RAIL systems HU | 1 |

| TARGAHORIS | Label plate for PATROL and H-RAIL systems IS | 1 |

| TARGAHORJA | Label plate for PATROL and H-RAIL systems JA | 1 |

| TARGAHORLT | Label plate for PATROL and H-RAIL systems LT | 1 |

| TARGAHORLV | Label plate for PATROL and H-RAIL systems LV | 1 |

| TARGAHORNL | Label plate for PATROL and H-RAIL systems NL | 1 |

| TARGAHORNO | Label plate for PATROL and H-RAIL systems NO | 1 |

| TARGAHORPL | Label plate for PATROL and H-RAIL systems PL | 1 |

| TARGAHORRO | Label plate for PATROL and H-RAIL systems RO | 1 |

| TARGAHORSK | Label plate for PATROL and H-RAIL systems SK | 1 |

| TARGAHORSL | Label plate for PATROL and H-RAIL systems SL | 1 |

| TARGAHORSV | Label plate for PATROL and H-RAIL systems SV | 1 |

| TARGAHORTR | Label plate for PATROL and H-RAIL systems TR | 1 |

| TARGAHORZH | Label plate for PATROL and H-RAIL systems ZH | 1 |

| TARGAHORAR | Label plate for PATROL and H-RAIL systems AR | 1 |