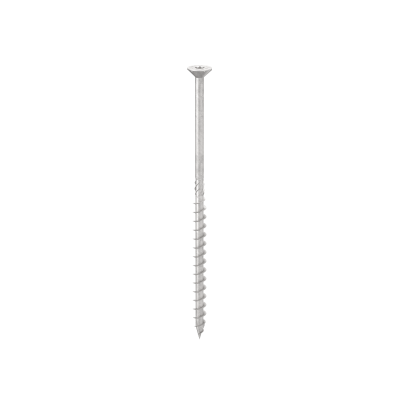

HBS EVO

HBS EVO is one of the strongest wood screws in an outdoor environment. The special surface treatment allows it to be used in service class 3 and in class C4 atmospheric corrosion conditions.

Description

Structural wood screws for outdoors and aggressive environments: choose the best, choose HBS EVO.

The special 20 μm multilayer C4 EVO coating with surface treatment of epoxy resin and aluminium flakes makes HBS EVO the perfect screw for application outdoors and in aggressive environments. It is approved for structural applications subject to stresses in any direction vs. the grain (α = 0° - 90°).

Asymmetric “umbrella” threading for excellent wood pull-through. HBS EVO is characterised by superior strength: the tests performed have shown that the steel has excellent failure and yield strength (fy,k = 1000 N/mm2) and very high torsional strength (ftor,k) for safer screwing. Certified for use in service class 3 outdoor applications and under class C4 atmospheric corrosion conditions.

Excellent for fastening framed panels and lattice beams (rafters, trusses), it offers superb performance in fastening on solid timber and glulam, CLT, LVL and high-density woods.

HBS EVO values are tested, certified and calculated for high-density woods.

Documents

-

Technical data sheets

- Technical data sheets Chinese

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets Dutch

- Technical data sheets English Eurocode 5

- Technical data sheets English USA NDS

- Technical data sheets English Canada CSA-086

- Technical data sheets Finnish

- Technical data sheets French

- Technical data sheets French Canada CSA-086

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Japanese CBL TS001-21

- Technical data sheets Korean

- Technical data sheets Latvia

- Technical data sheets Norwegian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovak

- Technical data sheets Slovene

- Technical data sheets Spanish

- Technical data sheets Swedish

-

Minimum Distances Guide

-

ICC-ES Evaluation report USA

-

ICC-ES Listing report CANADA

-

ETA Certificate

-

File CAD

-

File BIM.ifc

-

File BIM.rfa

HBS EVO

| CODE | info | d₁

[mm]

|

L

[mm]

|

b

[mm]

|

d₁

[in]

|

L

[in]

|

b

[in]

|

TX | pcs. |

DOP

|

|---|---|---|---|---|---|---|---|---|---|---|

| HBSEVO440 | - | 4 | 40 | 24 | 0.16 | 1 9/16'' | 15/16'' | TX20 | 500 | |

| HBSEVO450 | - | 4 | 50 | 30 | 0.16 | 1 15/16'' | 1 3/16'' | TX20 | 400 | |

| HBSEVO460 | - | 4 | 60 | 35 | 0.16 | 2 3/8'' | 1 3/8'' | TX20 | 200 | |

| HBSEVO4545 | - | 4.5 | 45 | 30 | 0.18 | 1 3/4'' | 1 3/16'' | TX20 | 400 | |

| HBSEVO4550 | - | 4.5 | 50 | 30 | 0.18 | 1 15/16'' | 1 3/16'' | TX20 | 200 | |

| HBSEVO4560 | - | 4.5 | 60 | 35 | 0.18 | 2 3/8'' | 1 3/8'' | TX20 | 200 | |

| HBSEVO4570 | - | 4.5 | 70 | 40 | 0.18 | 2 3/4'' | 1 9/16'' | TX20 | 200 | |

| HBSEVO4580 | - | 4.5 | 80 | 40 | 0.18 | 3 1/8'' | 1 9/16'' | TX20 | 200 | - |

| HBSEVO550 | - | 5 | 50 | 24 | 0.2 | 1 15/16'' | 15/16'' | TX25 | 200 | |

| HBSEVO560 | - | 5 | 60 | 30 | 0.2 | 2 3/8'' | 1 3/16'' | TX25 | 200 | |

| HBSEVO570 | - | 5 | 70 | 35 | 0.2 | 2 3/4'' | 1 3/8'' | TX25 | 100 | |

| HBSEVO580 | - | 5 | 80 | 40 | 0.2 | 3 1/8'' | 1 9/16'' | TX25 | 100 | |

| HBSEVO590 | - | 5 | 90 | 45 | 0.2 | 3 1/2'' | 1 3/4'' | TX25 | 100 | |

| HBSEVO5100 | - | 5 | 100 | 50 | 0.2 | 4'' | 1 15/16'' | TX25 | 100 | |

| HBSEVO660 | - | 6 | 60 | 30 | 0.24 | 2 3/8'' | 1 3/16'' | TX30 | 100 | |

| HBSEVO670 | - | 6 | 70 | 40 | 0.24 | 2 3/4'' | 1 9/16'' | TX30 | 100 | |

| HBSEVO680 | - | 6 | 80 | 40 | 0.24 | 3 1/8'' | 1 9/16'' | TX30 | 100 | |

| HBSEVO6100 | - | 6 | 100 | 50 | 0.24 | 4'' | 1 15/16'' | TX30 | 100 | |

| HBSEVO6120 | - | 6 | 120 | 60 | 0.24 | 4 3/4'' | 2 3/8'' | TX30 | 100 | |

| HBSEVO6140 | - | 6 | 140 | 75 | 0.24 | 5 1/2'' | 2 15/16'' | TX30 | 100 | |

| HBSEVO6160 | - | 6 | 160 | 75 | 0.24 | 6 1/4'' | 2 15/16'' | TX30 | 100 | |

| HBSEVO6180 | - | 6 | 180 | 75 | 0.24 | 7 1/8'' | 2 15/16'' | TX30 | 100 | |

| HBSEVO6200 | - | 6 | 200 | 75 | 0.24 | 8'' | 2 15/16'' | TX30 | 100 | |

| HBSEVO8100 | - | 8 | 100 | 52 | 0.32 | 4'' | 2 1/16'' | TX40 | 100 | |

| HBSEVO8120 | - | 8 | 120 | 60 | 0.32 | 4 3/4'' | 2 3/8'' | TX40 | 100 | |

| HBSEVO8140 | - | 8 | 140 | 60 | 0.32 | 5 1/2'' | 2 3/8'' | TX40 | 100 | |

| HBSEVO8160 | - | 8 | 160 | 80 | 0.32 | 6 1/4'' | 3 1/8'' | TX40 | 100 | |

| HBSEVO8180 | - | 8 | 180 | 80 | 0.32 | 7 1/8'' | 3 1/8'' | TX40 | 100 | |

| HBSEVO8200 | - | 8 | 200 | 80 | 0.32 | 8'' | 3 1/8'' | TX40 | 100 | |

| HBSEVO8220 | - | 8 | 220 | 80 | 0.32 | 8 5/8'' | 3 1/8'' | TX40 | 100 | |

| HBSEVO8240 | - | 8 | 240 | 80 | 0.32 | 9 1/2'' | 3 1/8'' | TX40 | 100 | |

| HBSEVO8260 | - | 8 | 260 | 80 | 0.32 | 10 1/4'' | 3 1/8'' | TX40 | 100 | |

| HBSEVO8280 | - | 8 | 280 | 80 | 0.32 | 11'' | 3 1/8'' | TX40 | 100 | |

| HBSEVO8300 | - | 8 | 300 | 100 | 0.32 | 11 3/4'' | 4'' | TX40 | 100 | |

| HBSEVO8320 | - | 8 | 320 | 100 | 0.32 | 12 5/8'' | 4'' | TX40 | 100 |