FLEXI BAND

FLEXI BAND universal tape provides excellent adhesion strength and resistance on all surfaces.

The special adhesive compound guarantees long-term functionality even under sub-optimal conditions, e.g. on dusty or damp surfaces.

Description

Flexi band universal tape, the perfect tape for users looking for a versatile tape of outstanding quality.

The combination of carrier and acrylic dispersion glue is designed for good adhesion even in extremely cold temperatures. Thanks to the special formulation of the acrylic glue, the universal tape FLEXI BAND achieves the highest level of safety against harmful emissions.

It is among the Rothoblaas solutions tested by the PassiveHouse Institute as airtight certified components.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Passive House Certificate

-

File BIM.rfa

-

Fire test report

-

EMICODE Certificate

FLEXI BAND

| CODE | liner | B

[mm]

|

L

[m]

|

liner

[in]

|

B

[in]

|

L

[ft]

|

pcs. |

|---|---|---|---|---|---|---|---|

| FLEXI60 | - | 60 | 25 | - | 2.4 | 82 | 10 |

| FLEXI100 | - | 100 | 25 | - | 3.9 | 82 | 6 |

| FLEXI5050 | 50/50 | 100 | 25 | 2/2 | 3.9 | 82 | 6 |

| FLEXI7575 | 75/75 | 150 | 25 | 3/3 | 5.9 | 82 | 4 |

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Thickness | EN 1942 | 0,32 mm | 13 mil |

| Tensile strength | EN 14410 | ≥ 50 N/25mm | ≥ 11.42 lbf/in |

| Water vapour transmission (Sd) | EN 1931 / EN ISO 12572 | ca. 45 m | ca. 0.078 US perm |

| Water vapour transmission (dry cup) | ASTM E96/ E96M | 0.11 US perm | - |

| Water vapour transmission (dry cup) | ASTM E96/ E96M | 6.27 ng/(s·m²·Pa) | - |

| Exposure to weather | - | > 6 month | - |

| Emicode | procedura di prova GEV | EC1 plus | - |

| Resistance to temperature | - | 40 / 80 °C | 104 / 176 °F |

| Application temperature | - | -18 / 40 °C | 0 / 104 °F |

| Storage temperature | - | 5 / 25 °C | 41 / 77 °F |

| Adhesion strength on steel at 90° | EN ISO 29862 | ≥ 30 N/25mm | ≥ 6.85 lbf/in |

| Adhesion strength on OSB at 180° after 10 minutes | EN ISO 29862 | 12 N/10mm | 6.9 lbf/in |

| Adhesion strength on OSB at 90° after 10 minutes | EN ISO 29862 | 6,5 N/10mm | 3.7 lbf/in |

| Adhesion strength (average) on membrane in PP after 24 hours | EN 12316-2 | 30 N/50mm | 3.4 lbf/in |

| Shear adhesion strength of the joint on membrane in PP after 24 hours (1 ) | EN 12317-2 | 70 N/50mm | 8 lbf/in |

| Solvents | - | no | - |

| VOC emissions | EN 16516 | very low | - |

| French VOC classification | ISO 16000 | A+ | - |

| Resistance to water penetration at 300Pa on wall | ASTM E331 | - | - |

| Fire resistance rating on CLT joint* (2 ) | en 1366-4 | EI90 | - |

Composition

| SUPPORT | PE film |

|---|---|

| GLUE | acrylic dispersion without solvents |

| REINFORCING LAYER | polyester reinforcing grid |

| GLUE | acrylic dispersion without solvents |

| RELEASE LINER | silicone coated paper |

Specifications

FLEXI BAND

Supply and installation of universal single-sided high-adhesion tape, Type FLEXI BAND.

Composition

From top layer to bottom layer:

PE film;

acrylic dispersion without solvents;

reinforcing polyester grid;

acrylic dispersion without solvents;

silicone coated paper.

Properties

Thickness [mm]: 0,32

Adhesion strength on OSB at 90° after 10 minutes [N/10 mm]: 6,5

Adhesion strength on OSB at 180° after 10 minutes [N/10 mm]: 12

Adhesion strength (average) on membrane in PP after 24 hours [N/50 mm]: 30

Shear adhesion strength of the joint on membrane in PP after 24 hours [N/50 mm]: 70

Tensile strength [N/25 mm]: ≥ 50

Water vapour transmission (Sd) [m] approx. 45

Exposure to weather: > 6 months

Application temperature [°C]: -18/+40

Resistance to temperature [C°]: -40/+80

Storage temperature [C°]: +5/+25

French VOC classification: A+

VOC emissions: very low

Solvents: no

Description

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

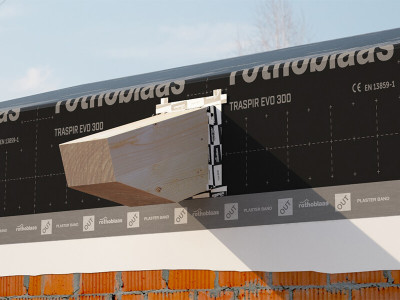

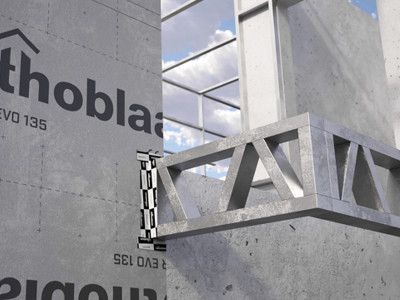

Recommended use: Suitable for application on various smooth building substrates, such as timber or OSB panels, without the need for additional surface treatment. If the tape is applied to brick or concrete surfaces, the use of a primer such as PRIMER SPRAY is recommended.

The complete list of approved application surfaces can be found in the specific instructions provided by the manufacturer.

The tape ensures excellent initial tack and superior adhesion strength even on dusty, porous or damp surfaces.

Installation: If applicable, the protective release film may be partially removed from the adhesive side to facilitate installation on both sharp-edged and flat surfaces. The sealing is completed by removing the remaining film and adhering the tape to the support.

Once tape installation is complete, a pressure roller must be used to ensure perfect adhesion.