BARRIER ALU NET ADHESIVE 300

The reflecting BARRIER ALU NET ADHESIVE 300 vapour and radon gas barrier screen is equipped with a fully self-adhesive membrane, which allows for quick and safe installation without compromising performance.

Thanks to its composition, the membrane is not affected by mechanical stress or by staples and nails.

Description

Composition

The top layer of this vapour barrier is a functional aluminised PE film. The middle layer consists of a PE reinforcement grid. The bottom layer is a PE film. The adhesive is a solvent-free acrylate dispersion. The separation layer is a pre-cut removable plastic film.

Performance

Water vapour transmission (Sd) = 4000 m (EN 1931 standard).

Thanks to its ability to reflect up to 70% of heat, the adhesive vapour control sheath improves the thermal performance of the construction panels.

The composition of this vapour barrier and the reinforcement grid guarantee excellent dimensional stability even under mechanical stresses.

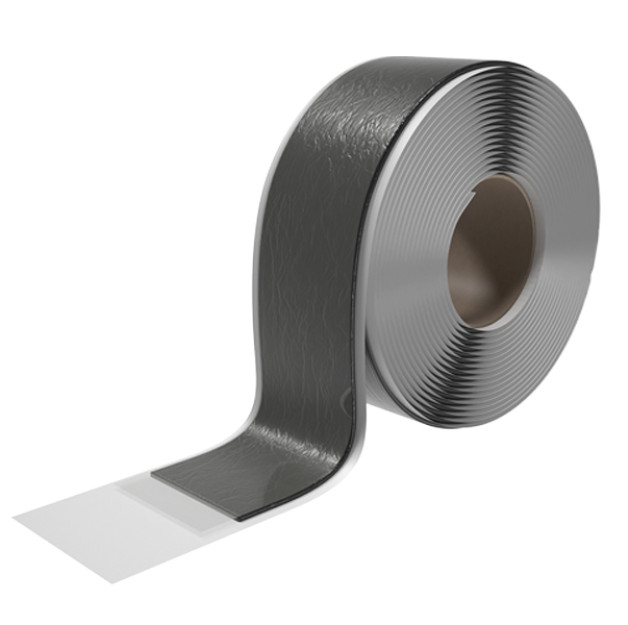

Sealing

Maximum resistance to the passage of water vapour and radon gas thanks to its special composition; ideal in combination with TERRA BAND UV and ALU BUTYL BAND for the perfect sealing of joints on site. The membrane, tested according to ISO/TS 11665-13, protects the building's perimeter and foundation structures, while minimising the presence of radon and eliminating health risks.

Vapour barrier where it is put

This adhesive barrier is placed inside the walls, floor or roof of a building to reduce the transmission of moisture through the structure. Its main objective is to prevent moisture condensation inside the walls, which could cause structural damage and mould problems. The membrane is also used to prevent the passage of radon gas indoors and avoid its harmful effects on health.

The exact location of the vapour barrier may vary depending on the type of construction and project specifications, but in general, it is placed on the warm side of the structure. The warm side is closest to the interior spaces of the building, where a higher temperature is maintained than outside.

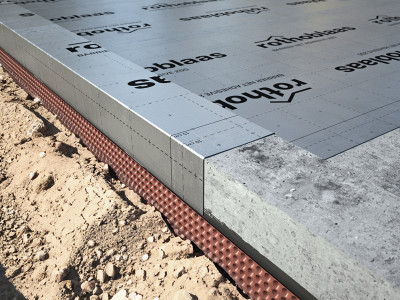

The underfloor vapour barrier generally serves to protect the screed from rising damp and condensation, and is therefore applied before the screed is constructed. In the case of foundation floors, it also offers protection against radon gas infiltration.

The vapour barrier on interior walls will be placed on the inner side of the wall, between the inner cladding (e.g. plaster or gypsum boards) and the outermost layer.

The roof vapour barrier will be placed on the inner side of the roof structure, under the insulation and close to the living spaces.

In addition, the vapour barrier must be placed so that it is continuous, avoiding cracks or breaks that could allow moisture to pass through. It is essential to follow the designer's instructions or manufacturer's specifications to ensure proper installation.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

File BIM.rfa

-

Xml-File WUFI

-

Recommendations for installation

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 300 g/m² | 0.98 oz/ft² |

| Thickness | EN 1849-2 | 0,15 mm | 6 mil |

| Water vapour transmission (Sd) | EN 1931 | 4000 m | 0.001 US perm |

| Tensile strength MD/CD | EN 12311-2 | > 400 / 400 N/50mm | > 46 / 46 lbf/in |

| Elongation MD/CD | EN 12311-2 | > 10 / 10 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | > 300 / 300 N | > 67 / 67 lbf |

| Watertightness | EN 1928 | compliant | - |

| Reaction to fire | EN 13501-1 | class B-s1,d0 | - |

| Resistance to penetration of air | EN 12114 | 0,02 m³/(m²·h·50Pa) | 0.001 cfm/ft² at 50Pa |

| Resistenza al vapore d'acqua dopo invecchiamento artificiale | EN 1296 / EN 1931 | compliant | - |

| Thermal conductivity (λ) | - | ca. 0,39 W/(m·K) | ca. 0.23 BTU/(h·ft·°F) |

| Specific heat | - | ca. 1700 J/(kg·K) | - |

| Density | - | ca. 600 kg/m³ | - |

| Water vapour resistance factor (μ) | - | 10000000 | - |

| Reflectivity | EN 15976 | 70 % | - |

| UV stability | - | 336h (3 months) | - |

| Exposure to weather | - | 4 weeks | - |

| Equivalent thermal resistance with 50mm air gap (ε 0,025-0,88) | ISO 6946 | 0,801 / 0,406 (m²·K)/W | 4.55 / 2.31 (h·ft²·°F)/BTU |

| Adhesion strength on OSB at 180° after 10 minutes | EN ISO 29862 | 4,5 N/10mm | 2.6 lbf/in |

| Adhesion strength on OSB at 90° after 10 minutes | EN ISO 29862 | 2 N/10mm | 1.1 lbf/in |

| Shear adhesion strength of the overlap after 24 hours | EN 12317-2 | 180 N/50mm | 20.6 lbf/in |

| Adhesion strength (average) of the overlap after 24 hours | EN 12316-2 | 25 N/50mm | 2.9 lbf/in |

| Storage temperature | - | 5 / 25 °C | 41 / 77 °F |

| Application temperature | - | -5 / 35 °C | 23 / 95 °F |

| Solvents | - | no | - |

Composition

| TOP LAYER | functional aluminised PE film |

|---|---|

| middle layer | PE reinforcing grid |

| BOTTOM LAYER | PE functional film |

| GLUE | acrylic dispersion without solvents |

| RELEASE LINER | removable plastic film |

Specifications

BARRIER ALU NET ADHESIVE 300

Supply and installation of Self-adhesive reflective vapour barrier Sd > 1500 m, like BARRIER ALU NET ADHESIVE 300.

Composition

From top layer to bottom layer:

PET film;

aluminium film;

PE film;

PE reinforcing grid;

PE film;

acrylic dispersion without solvents;

precut removable plastic film.

Properties

Mass per unit area [g/m²]: 300

Thickness [mm]: 0,15

Water vapour transmission (Sd)[m]: 4000

Tensile strength MD/CD [N/50 mm]: >400/400

Elongation MD/CD [%]: >10/10

Resistance to nail tearing MD/CD [N]: >300/300

Watertightness: compliant

Reaction to fire: class B-s1, d0 (EN 13501-1)

Resistance to temperature [°C]: -20/80

UV stability: 336h (3 months)

Radon diffusion coefficient D [m2/s]: < 3.5 e^-15

Radon diffusion length l [m]: < 0,000041

Reflectivity [%]: approx. 70

Storage temperature [°C]: 5/25

Application temperature [°C]:- 5/35

Solvents: no

Standards and certifications

CE marked in accordance with EN 13984

AUS 4200.1 Class 1

Description

The membrane can be used both as temporary protection during construction and transport phases, and as a long-term functional layer in building components (walls and floors).

The application surface must be dry, free of dust and grease, and not be anti-adhesive. Surface elements must be removed so that the membrane is not damaged during application.

The membrane includes a reinforcement mesh that provides high resistance to mechanical stresses caused by staples, nails, or wear when walked on.

Recommended use: direct UV protection is guaranteed. Installation is therefore permitted on both the internal and external sides of the building envelope.

Thanks to its ability to reflect up to 70% of the heat, the membrane improves the thermal performance of the construction panels.

Installation within the walls, floor, or roof of the building is required to effectively block moisture transmission through the structure. The membrane can also be used to prevent the passage of radon gas indoors and avoid its harmful effects on health.

The exact location of the vapour barrier may vary depending on the type of construction and project specifications, but in general, it is placed on the warm side of the structure.

Installation: Unroll the membrane over the surface to be protected, progressively remove the release film from the adhesive, and press the membrane firmly to ensure proper adhesion.

Ensure that the overlap between the membranes is at least 15 cm to achieve an optimal seal.

To ensure correct and professional installation, the use of a nail sealing point is required.

Further details regarding installation can be found in the specific instructions provided by the supplier.