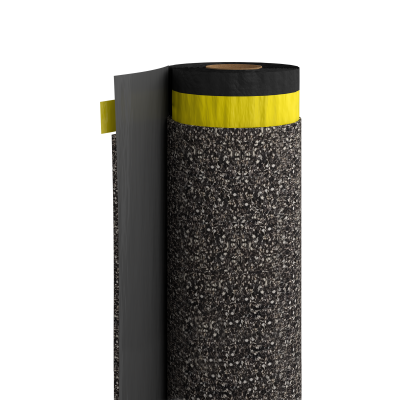

SILENT FLOOR PUR

SILENT FLOOR PUR is the highest performing sound insulation in the SILENT FLOOR family. Properly applied in the underscreed, the product increases the acoustic performance of the finished floor. It is also an excellent supplementary solution for impact noise and floor soundproofing of timber, steel or masonry structures.

APPLICATIONS

- Combined with resilient profiles, it solves the problem of structure-borne noise

- Underscreed application makes it effective against impact noise and provides excellent soundproofing

- Also suitable for the renovation of vertical partitions, it works as acoustic insulation applied to supporting walls

Thanks to the special polyurethane compound, it offers excellent elasticity and achieves impact noise attenuation values of over 30 dB.

Description

SILENT FLOOR PUR: high soundproofing.

Added to its excellent soundproofing performance, SILENT FLOOR PUR is a sustainable product because it consists of polyurethane derived from production waste. It is recycled and recyclable.

As a noble polymer, polyurethane maintains elasticity over time without subsidence or changes in performance, ensuring product durability.

SILENT FLOOR PUR is made combining a waterproof membrane with a resilient component obtained from recycling latex and foam rubber. Its effectiveness as a sound-absorbing and insulating material has been approved in the laboratories of the Industrial Research Centre of the University of Bologna and the Building Envelope Lab of the Free University of Bolzano.

It does not contain substances harmful for people and the environment.

Documents

-

Technical data sheets

-

Technical Manual

SILENT FLOOR PUR

| CODE | H

[m]

|

L

[m]

|

s

[mm]

|

A

[m²]

|

pcs./pallet |

|---|---|---|---|---|---|

| SILFLOORPUR10 | 1.6 | 10 | 10 | 16 | 6 |

| SILFLOORPUR15 | 1.6 | 8 | 15 | 12.8 | - |

| SILFLOORPUR20 | 1.6 | 6 | 20 | 9.6 | 6 |

Specifications

SILENT FLOOR PUR

Supply and installation of high-performance resilient underscreed foil made from recycled polymers, Type SILENT FLOOR PUR.

Composition

From top layer to bottom layer:

- polyethylene vapour barrier;

-polyurethane agglomerate made from pre-consumer industrial waste.

Properties

-

Resistance to airflow r [kPa·s·m^-2]: < 10,0

-

Compressibility class: CP2

-

CREEP Viscous sliding under compression Xct (1,5 kPa)[%]: 7,5

-Compression deformation stress [kPa]: 17

-

Thermal conductivity λ [W/(m·K)]: 0,035

-

Specific heat c [J/kg·K]: 1800

-

Water vapour transmission Sd [m]: > 100

-

Reaction to fire (EN 13501-1): class F

-

VOC emission classification: A+

-

Surface mass m [kg/m^2]: 0,9 ÷ 1,8

-

Density ρ [kg/m^3]: 80 ÷ 90

-

Apparent dynamic stiffness s’t [MN/m^3]: 7,4 ÷ 12,5

-

Dynamic stiffness s’ [MN/m^³]: 7,4 ÷ 12,5

-

Theoretical estimate of impact sound pressure level reduction ΔLw [dB]: 32,5 ÷ 35,7

-System resonance frequency f0 [Hz]: 38,9 ÷ 50,6

-

Impact sound pressure level attenuation ΔLw [dB]: 21 ÷ 25

-

Thermal resistance Rt [m^2K/W]: 0,46 ÷ 0,92

Description

Resilient underscreed foil used to enhance impact noise insulation and increase the overall soundproofing performance of the finished floor slab. -This is a waterproof membrane coupled with a resilient component made from recycled latex and foam rubber.

The impact sound insulation system is composed of these two elements, with an integrated adhesive flap to simplify overlapping between rolls.

The product is recyclable, rot-proof, insoluble in water, and non-irritating to skin, eyes, or respiratory system.

Installation is made easier by the integrated adhesive band, allowing immediate attaching of the selvedges to the overlaps.

Installation

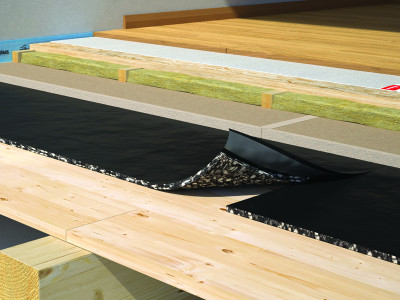

It is typically used in new constructions, following the design and application principles of the “floating screed” system.

The resilient layer must be continuous because any discontinuation would represent an acoustic bridge.

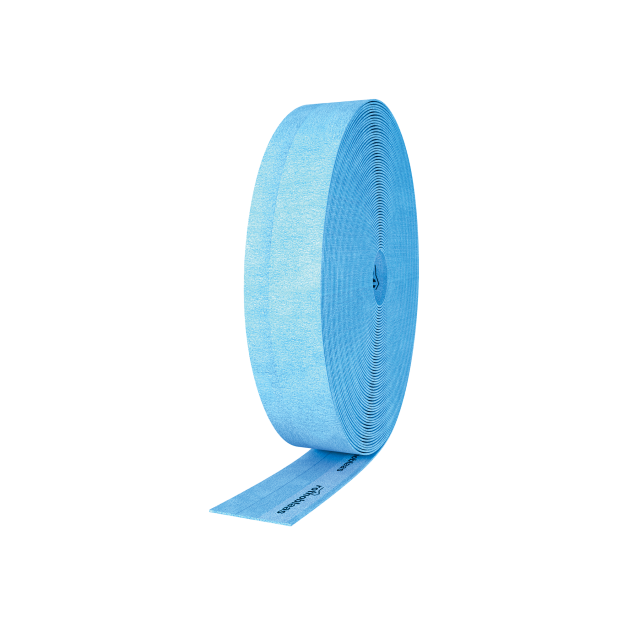

It is important to use a perimeter strip to ensure that the resilient layer is continuous around the entire perimeter of the room. The perimeter strip should only be trimmed after the floor has been installed and grouted.

The system must be installed in accordance with the instructions and warnings provided by the manufacturer to ensure compliance and long-term performance.