SILENT STEP ALU

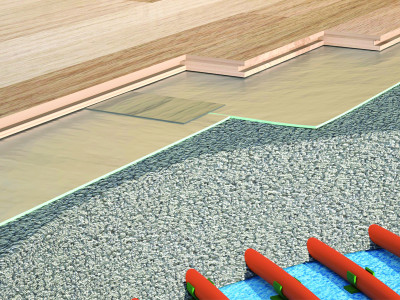

An excellent acoustic floor insulation, SILENT STEP ALU is a substrate with an aluminium vapour barrier to protect against rising damp.

APPLICATIONS

- Specific for floating installation of parquet, laminates

- Suitable for radiant floors

Description

SILENT STEP ALU is a very versatile product. It is applied a soundproofing insulation for the floor and, at the same time, protects it from rising damp thanks to the aluminium coating. Fire reaction class Bfl - s1.

SILENT STEP ALU is chemically stable and does not contain harmful substances or VOCs.

Documents

-

Technical data sheets

SILENT STEP ALU

| CODE | H

[m]

|

L

[m]

|

s

[mm]

|

A

[m²]

|

pcs./pallet |

|---|---|---|---|---|---|

| SILENTSTEPA | 1 | 8.5 | 2 | 8.5 | 40 |

Specifications

SILENT STEP ALU

Supply and installation of high-density polymer substrate with aluminium coating and integrated vapour barrier film, Type SILENT STEP ALU.

Properties

-

Thickness [mm]: 1.8

-

Density ρ [kg/m^3]: 555

-

Water vapour transmission Sd [m]: ≥ 150

-

Compression strength CS [kPa]: 300

-

Reaction to fire: class Bfl-s1

-

VOC emission classification: A+

Description

High-density polymer substrate covered in aluminium, designed to function both as an acoustic insulation layer and as protection against rising damp in floor assemblies. The aluminium layer acts as a vapour barrier, preventing moisture penetration and helping preserve and extend the durability of flooring in systems with floating floor installations (not suitable for glued floors).

The high-density polymer structure efficiently absorbs and reduces impact noise.

The material is chemically stable, durable, and free from VOCs or harmful substances. Its fire reaction classification Bfl - s1 allows for use in environments with specific fire safety requirements.

Installation

The application surface must be dry, free of dust and grease. Surface elements must be removed so that the membrane is not damaged during application. Any interruption in the resilient layer may compromise acoustic performance. Install the membrane with the aluminium side facing upward, and ensure continuity by sealing the joints with suitable tapes such as FLEXY BAND, SPEEDY BAND or EASY BAND, to maintain long-term airtightness and performance. Further details regarding installation can be found in the specific instructions provided by the supplier.