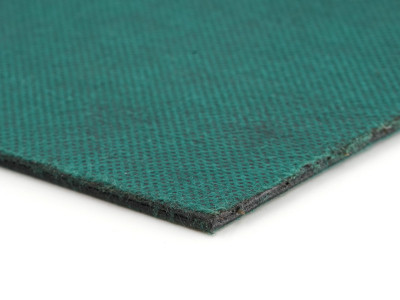

SILENT WALL BYTUM

SOUNDPROOFING AND WATERPROOFING BITUMINOUS MEMBRANE

Installed inside the counter wall or false ceiling, the SILENT WALL BYTUM sheet ensures an excellent reduction in airborne noise transmission.

Made of elastoplastomeric bitumen, it has a high surface mass (6 kg/m²) and minimal thickness: these two features make it a perfect soundproofing waterproofing sheet.

APPLICATIONS

- Ideal in all situations where an increase in mass is required to increase soundproofing power and reduce airborne noise transmission

- Suitable for all situations where there is a need to achieve great performance in a small space

The soundproofing power of SILENT WALL BYTUM in different configurations and stratigraphies has been tested by the Free University of Bolzano according to EN ISO 10140-2.

Documents

-

Technical data sheets

-

Technical Manual

SILENT WALL BYTUM

| CODE | H

[m]

|

L

[m]

|

s

[mm]

|

A

[m²]

|

pcs./pallet |

|---|---|---|---|---|---|

| SILWALL | 1.2 | 5 | 4 | 6 | 30 |