TRASPIR METAL

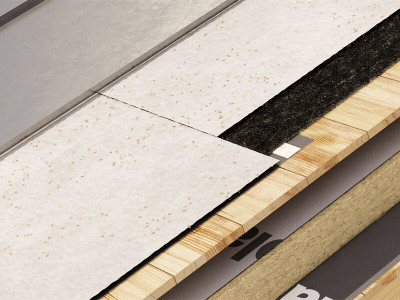

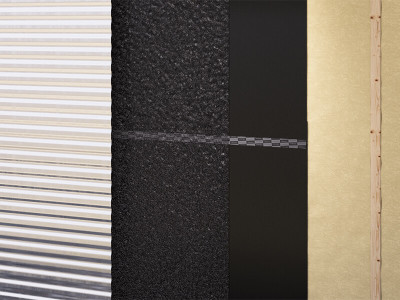

Installed on a continuous support, the TRASPIR METAL three-dimensional mat for soundproofing facilitates the micro-ventilation of metal roofs, stopping them from corroding and thus increasing their durability. The TRASPIR METAL range is complete: it is available with lower breathable impermeable membrane and with upper TNT draining layer.

Description

TRASPIR METAL: the only solution of its kind tested on site from the point of view of sound insulation against rain beating on the roof.

Highly breathable membrane paired with a 3D mat and protective felt. The top felt prevents impurities from getting into the mat and improves resistance to treading, preventing water stagnation. The effectiveness of TRASPIR METAL as a solution for sound insulation against the noise from heavy rain is certified by the Giordano Institute.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

-

Declaration of performance (DOP)

-

TEST REPORT AUS/NZ

TRASPIR 3D COAT TT

| CODE | description | tape | H

[m]

|

L

[m]

|

A

[m²]

|

H

[ft]

|

L

[ft]

|

A

[sft]

|

pcs./pallet |

|---|---|---|---|---|---|---|---|---|---|

| TTTMET610 | TRASPIR 3D COAT TT | TT | 1.35 | 33 | 44.55 | - | 108 | 480 | 4 |

3D NET

| CODE | description | tape | H

[m]

|

L

[m]

|

A

[m²]

|

H

[ft]

|

L

[ft]

|

A

[sft]

|

pcs./pallet |

|---|---|---|---|---|---|---|---|---|---|

| NET350 | NET 350 | - | 1.25 | 50 | 62.5 | - | 164 | 673 | 4 |

Technical Data TRASPIR 3D COAT TT

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 600 g/m² | 1.97 oz/ft² |

| Thickness | EN 1849-2 | 8 mm | 315 mil |

| Water vapour transmission (Sd) | EN 1931 | 0,025 m | 139.86 US perm |

| Tensile strength MD/CD | EN 12311-1 | 300 / 225 N/50mm | 34 / 26 lbf/in |

| Elongation MD/CD | EN 12311-1 | > 35 / 50 % | - |

| Resistance to nail tearing MD/CD | EN 12310-1 | 175 / 150 N | 39 / 34 lbf |

| Watertightness | EN 1928 | class W1 | - |

| Resistance to temperature | - | -40 / 80 °C | -40 / 176 °F |

| Reaction to fire | EN 13501-1 | class E | - |

| Resistance to penetration of air | EN 12114 | < 0,02 m³/(m²·h·50Pa) | < 0.001 cfm/ft² at 50Pa |

| Thermal conductivity (λ) | - | 0,3 W/(m·K) | 0.17 BTU/(h·ft·°F) |

| Specific heat | - | 1800 J/(kg·K) | - |

| Density | - | ca. 75 kg/m³ | - |

| Water vapour resistance factor (μ) | - | ca. 33 | - |

| UV stability (1 ) | - | 336h (3 months) | - |

| Water column | ISO 811 | > 250 cm | > 98 in |

| Watertightness after artificial ageing | EN 1297 / EN 1928 | class W1 | - |

| After artificial ageing - Tensile strength MD/CD | EN 1297 / EN 12311-1 | 285 / 185 N/50mm | 33 / 21 lb/in |

| After artificial ageing - elongation | EN 1297 / EN 12311-1 | 35 / 30 % | - |

| Flexibility at low temperatures | EN 1109 | -40 °C | -40 °F |

| Void ratio | - | 95 % | - |

| Attenuation of the sound reduction index ΔRw | ISO 10140-2 / ISO 717-1 | 1 dB | - |

| Attenuation in overall A-weighted sound intensity level from heavy rain noise ΔLiA | ISO 140-18 | ca. 4 dB | - |

| VOC | - | not relevant | - |

| Impact sound pressure level attenuation ΔLw (2 ) | ASTM E492 | 15 dB | - |

Technical Data 3D NET

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Mass per unit area | EN 1849-2 | 350 g/m² | 1.15 oz/ft² |

| Thickness | EN 1849-2 | 7,5 mm | 295 mil |

| Maximum tensile force MD/CD NET | EN 12311-1 | 1,3 / 0,5 N/50mm | 0 / 0 lb/in |

| Elongation MD/CD NET | EN 12311-1 | 95 / 65 % | - |

| Resistance to temperature | - | -40 / 80 °C | -40 / 176 °F |

| Reaction to fire | EN 13501-1 | class F | - |

| Thermal conductivity (λ) | - | 0,3 W/(m·K) | 0.17 BTU/(h·ft·°F) |

| Specific heat | - | 1800 J/(kg·K) | - |

| Density | - | ca. 45 kg/m³ | - |

| UV stability (1 ) | - | 336h (3 months) | - |

| Void ratio | - | 95 % | - |

| Attenuation of the sound reduction index ΔRw | ISO 10140-2 / ISO 717-1 | 1 dB | - |

| Attenuation in overall A-weighted sound intensity level from heavy rain noise ΔLiA | ISO 140-18 | 4 dB | - |

| VOC | - | not relevant | - |

Composition TRASPIR 3D COAT TT

| protection layer | non-woven PP fabric |

|---|---|

| 3D grid | 3-dimensional PP mat |

| TOP LAYER | non-woven PP fabric |

| middle layer | PP breathable film |

| BOTTOM LAYER | non-woven PP fabric |

Composition 3D NET

| 3D grid | 3-dimensional PP mat |

|---|

Specifications

TRASPIR 3D COAT TT

Supply and installation of three-dimensional mat for metal roofing, Type TRASPIR 3D COAT TT.

Composition

From top layer to bottom layer:

-

3-dimensional PP mat

-

non-woven PP fabric

-

PP breathable film

-

non-woven PP fabric

Properties

-

Mass per unit area [g/m²]: 600

-

Thickness [mm]: 8

-

Water vapour transmission Sd [m]: 0.025

-

Tensile strength MD/CD [N/50 mm]: 300/220

-

Elongation MD/CD [%]: > 35/50%

-

Resistance to nail tearing MD/CD [N]: 150/175

-

Watertightness: class W1

-

Thermal resistance [C°]: -40/80

-Reaction to fire: class E

-

Density ρ [kg/m^3]: 75

-

Water vapour resistance factor μ: 33

-

VOC content: < 0.02%

-

Exposure to weather: 2 weeks

-

Watertightness after artificial ageing: W1 class

-

Tensile strength MD/CD after artificial ageing [N/50mm]: > 240/155

-

Elongation after artificial ageing: > 30/40%

Description

Highly breathable membrane paired with a 3D mat and protective felt. The upper felt layer prevents impurities from entering the mat and improves resistance to treading, while promoting micro-ventilation beneath metal roofing systems and preventing water stagnation underneath, thus reducing the risk of corrosion.

Installation

The application surface must be dry, free of dust and grease. Surface elements must be removed so that the membrane is not damaged during application. Further details regarding installation can be found in the specific instructions provided by the supplier.