Installing screws securely and avoiding premature failure with Rothoblaas tools

For safe screw installation and dispute-proof design

Timber-to-metal connections are critical points in any engineered timber structure. This isn't a minor detail: it's where materials with different mechanical, hygrometric and chemical properties come together. It is here that localised stress, differential deformation and potential failures tend to concentrate, often triggered by design errors or poor choices on site.

Anyone designing these connections needs to handle the structural calculations, but also carefully consider all the other factors involved in ensuring their proper performance.

– Differences in stiffness and behaviour under load between timber and steel

– Timber swelling and shrinkage due to varying humidity levels

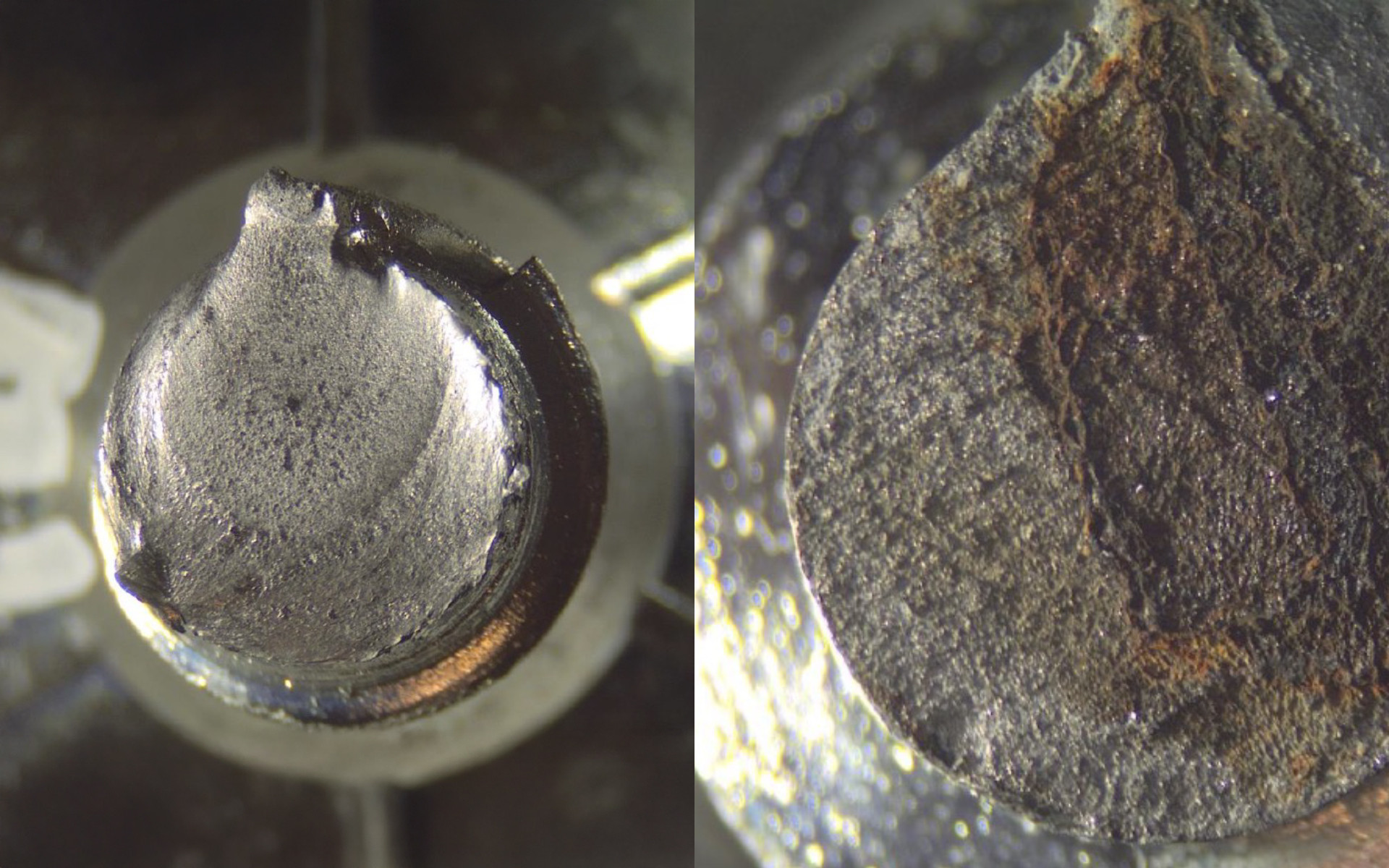

– Atmospheric corrosion, timber corrosiveness and galvanic corrosion

– Risks of hydrogen embrittlement

– Installation requirements such as torque control, installation angles, pilot holes, etc.

– Metal deformation due to temperature changes (thermal expansion)

These aren't just hypothetical scenarios – they are the real causes of premature connection failure on many building sites. The difference between a joint that lasts 50 years and one that fails can come down to these very details.

At Rothoblaas, we took on this challenge and have now developed a full range of tools to support designers.

In addition to our extensive and active contribution to the Mass Timber sector in preventing premature failure, we have also created a toolkit that gives designers what they need to prevent screw failure and related issues:

Smartbook and Installation Manuals for on-site consultation

Minimum fastening requirements for inclusion in the project specifications, available at the end of this article

An exclusive interactive risk assessment tool will also soon be available.

Ready-to-use specifications for project documentation: reduce risk, improve connections

To support designers in preparing their technical drawings, Rothoblaas has developed a set of Recommended Item Specifications ready to be integrated, customised and attached directly to your project specification documents.

These specifications are drawn from Rothoblaas’s extensive experience in over 130 countries, the technical analysis of documented cases of premature failure presented in our Whitepaper, and our active role in international standards committees. The aim is to provide a clear, technical and practical reference to help reduce the risk of errors in the selection and installation of structural fasteners.

The entries that follow can be copied and pasted in full or tailored by selecting the relevant sections for your project (for instance, by omitting references to non-applicable standards). They are particularly useful for timber-to-metal connections, which are consistently among the most critical for:

Unexpected localised stress

Differential stiffness

The risk of hydrogen embrittlement or hydrogen-induced stress corrosion cracking

Note that these specifications represent minimum requirements, intended as a technical guide for responsible, well-informed design. They are not a substitute for a full engineering assessment, nor for adjustments based on static loads, environmental conditions or specific performance requirements.

The specifications presented here are intended to:

Provide a shared technical language between designer, contractor and supplier

Reduce the margin for disputes in the event of defects or failure

Simplify communication during site supervision and construction stages

The designer remains fully responsible for all technical decisions, structural calculations and any requirements included in their project documentation. Certain national or local regulations may impose stricter requirements than those listed below.

General minimum requirements for Rothoblaas structural fasteners

1. Regional compliance

All fasteners used in timber construction must meet or exceed the relevant regional standards:

Europe: EN 14592 or ETA (European Technical Assessment) according to EAD 130118-01-0603, in support of Eurocode 5 (EN 1995-1).

USA: ICC-ES AC233 and/or NDS (National Design Specification).

Canada: ICC-ES AC233 and/or CSA O86:2024.

Other regions: Refer to current national standards and approvals.

2. Third-party approval

Where required, fasteners and installation procedures must be reviewed and approved by a qualified third-party professional, for example:

North America: Structural Engineer of Record (EOR)

Germany: Prüfingenieur

Italy: Collaudatore

3. Core hardness

Self-drilling fasteners made of case-hardened steel used in metal-to-timber connections must have a maximum core hardness of 390 HV (ISO 2702) to reduce the risk of hydrogen embrittlement.

4. Exposure to moisture

Fasteners exposed to damp service conditions or prolonged humidity (also during construction) must not only comply with the project’s corrosion resistance requirements, but also satisfy the following:

core hardness ≤ 360 HV, or

specify stainless steel fasteners or those with high-performance protective coatings (e.g. EVO coating)

5. Moisture Control Plan (MCP)

A Moisture Control Plan should be developed to ensure that timber elements and joints remain within acceptable limits:

Service class 1 and 2 / dry service conditions: Recommended average MC <16%, never exceeding 19%.

6. Quality management against hydrogen embrittlement (HE)

All fasteners must follow a quality control process that includes:

Prevention of hydrogen embrittlement (use of pickling inhibitors, controlled galvanising)

If necessary, post-coating dehydrogenation heat treatments in accordance with ISO 4042 or ASTM F1941

7. IHE continuous load test

Fasteners must successfully pass continuous load testing for internal hydrogen embrittlement in compliance with ISO 15330 or ASTM F606 Clause 7.

8. Coating requirements

For electroplated galvanised fasteners:

Coating in compliance with ISO 4042, minimum thickness 8 μm

Must pass salt spray test in accordance with ISO 9227

9. Installation practices

Fasteners must be installed strictly following the manufacturer’s instructions, including:

Any required pilot drilling

Maximum tightening torque

Angular tolerances

10. Metal-to-timber insertion control

In metal-to-timber connections:

Deviation from the designed axis of maximum ±5°

Tightening torque must comply with the installation manual

Unless otherwise specified, never exceed 65% of the fastener’s characteristic torsional capacity

11. On-site storage

Fasteners must be:

Stored in dry, protected environments

Shielded from direct water exposure during all stages of construction

Why adopting these specifications means reducing the risk of fastener failure

These specifications provide a clear and comprehensive baseline that helps reduce the risk of errors during the selection, design and installation of connections. A shared technical language streamlines communication between designers, contractors and suppliers and helps prevent future disputes.

Rothoblaas supports engineers and designers with certified fasteners, detailed technical data sheets and BIM libraries, making it easy to integrate these specifications into your projects.

But it doesn’t end there.

We're also developing an interactive risk assessment tool: simply input the key factors and receive your assessment.

Because Research & Development doesn't just mean “inventing new products” – it also means creating tools that simplify the work of the professionals who use them, providing “ready-made” solutions for a profession that is anything but simple.

All the upcoming tools will be available free of charge on our website. In the meantime, for any questions: https://www.rothoblaas.com/technical-support

All rights reserved