SHARP METAL

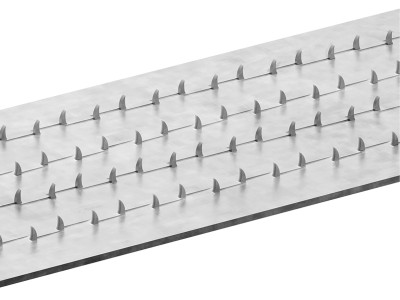

SHARP METAL steel hooked plates have a multitude of small hooks spread all over the surface. The joint between the two timber elements is made by the mechanical engagement of the metal hooks in the timber. The system is non-invasive can be uninstalled.

Description

SHARP METAL, hooked plates for timber-to-timber connections.

The large number of hooks distributed over the entire surface of the metal plates generates a biting grip in the timber with exceptional strength and stiffness values. Hooked plates allow the transfer of shear stresses between two timber surfaces, achieving performances comparable to those of gluing.

This eliminates concentrated forces, reduces the problem of minimum distances and optimises the thickness of the steel (0.75 mm) that can be screwed without pre-drilling with HBS and TBS screws for tightening the joint. Thanks to the hook technology, the SHARP METAL system is ideal for the production of ribbed floors (Rippendecke, ribbed floor) without the use of glues, adhesives and presses and eliminating the waiting time for the glue to set and harden.

Made of carbon steel with an electrolytic coating, SHARP METAL hooked plates are ideal for shear joints between timber surfaces, solid and laminated timber, CLT, LVL and timber-based panels.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovak

- Technical data sheets Slovene

- Technical data sheets Spanish

-

ETA Certificate

-

File BIM.ifc

-

File BIM.rfa