TC FUSION

The problem of creating a CLT floor that is sufficiently rigid to allow a large distance between load-bearing columns is no longer an issue. For transport reasons, the panels cannot be very wide (usually a maximum of 3.5 m) and in order to connect them together sufficiently rigidly, they are glued in the construction site.

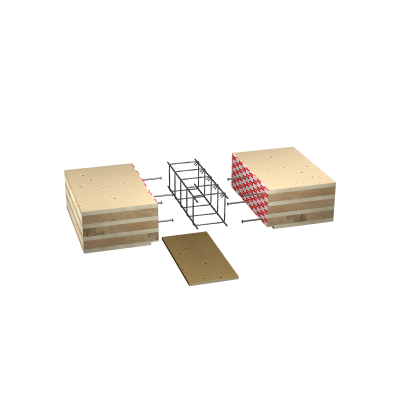

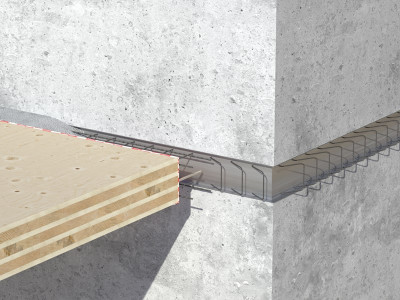

The Rothoblaas TC FUSION system, on the other hand, allows panels to be joined no longer by gluing, but by a timber-concrete-timber connection. Thanks to the stiffness of reinforced concrete, the resulting CLT floor is particularly resistant to deformation and vibration, allowing the full potential of the SPIDER and PILLAR systems to be exploited.

Description

Applications

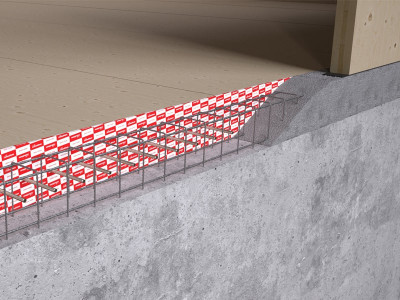

The TC FUSION system obviously finds its place not only in floors, but in a multitude of situations where a CLT panel must be rigidly connected to a reinforced concrete element. For example, it is possible to create the support of a CLT floor on a reinforced concrete wall, or to use the system to connect CLT walls to the ground or to connect CLT walls to reinforced concrete.

How TC FUSION works

The VGS, VGZ and RTR full-thread connectors are now certified for any type of application where a timber element (wall, ceiling, etc.) must transmit stresses to a concrete element (bracing core, foundation, etc.).

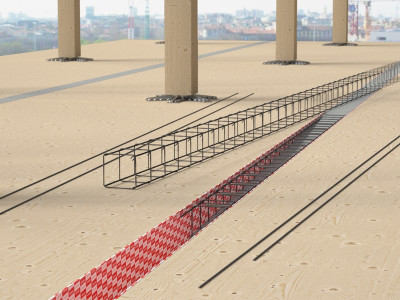

The concrete prefabrication combines with timber prefabrication: the reinforcing bars inserted into the concrete casting accommodate the full thread timber connectors; the supplementary casting carried out after installing the timber components completes the connection.

TC FUSION enables connections between CLT panels with exceptional strength and stiffness for shear, bending moment and axial stress.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English Eurocode 5

- Technical data sheets English USA NDS

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovak

- Technical data sheets Slovene

- Technical data sheets Spanish

-

ETA Certificate

-

Calculator Spreadsheet TC FUSION