XYLOFON

Walls soundproofing of a timber, steel or masonry structure is an essential comfort.

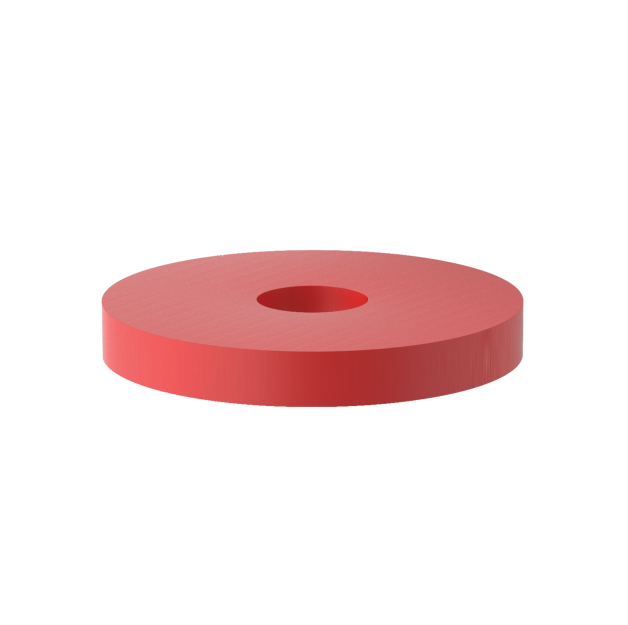

XYLOFON is the resilient profile that provides maximum soundproofing through its ability to solve the problem of structure-borne noise.

It is a certified product according to ETA and EPD standards for environmental impact.

APPLICATIONS

• Tested and certified to separate building materials (desolidarisation phenomena and mechanical interruption)

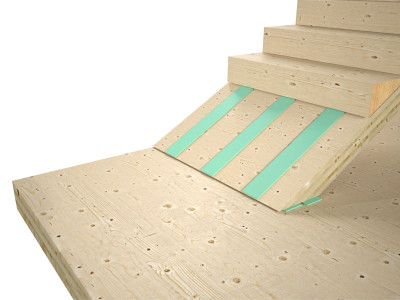

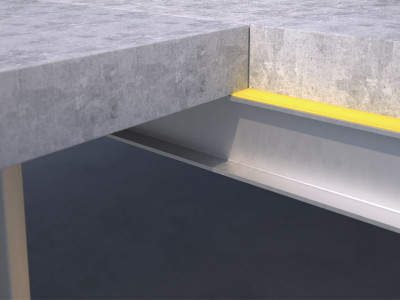

• Suitable for CLT, LVL, steel and concrete

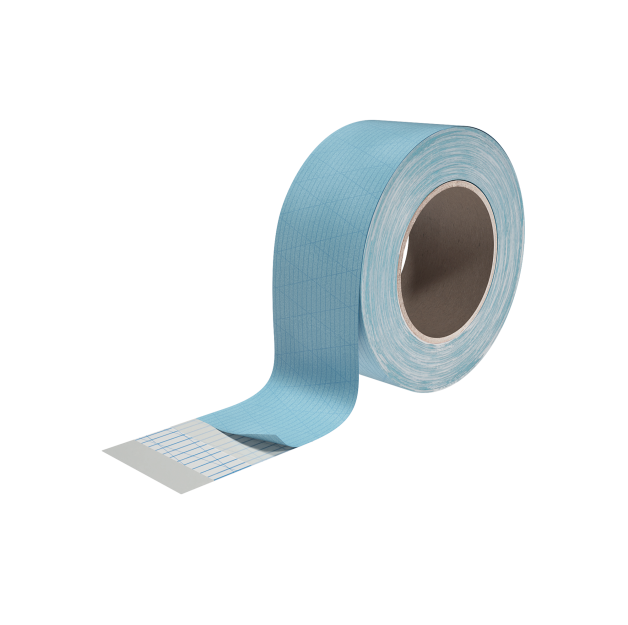

• Applicable with staples, PRIMER SPRAY, DOUBLE BAND

• For soundproofing walls and floors connected with angle brackets

The monolithic polyurethane structure means that the XYLOFON range offers tested acoustic improvement values ranging from 6 dB to over 15 dB.

Description

CHARACTERISTICS

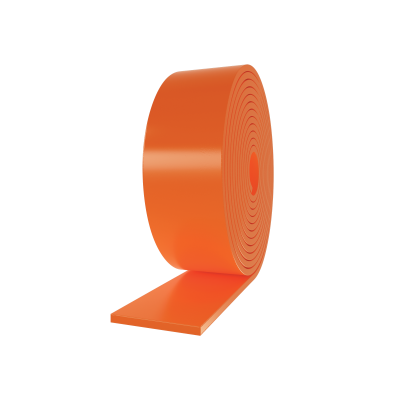

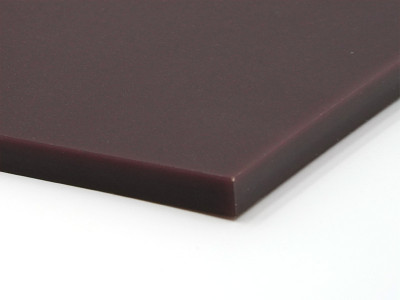

• Made of a polyurethane compound, XYLOFON is a monolithic profile that maintains water tightness, stability and long-term elastic properties

• Available in 6 variants with 6 different hardnesses capable of withstanding a wide range of loads without affecting design choices and allowing controlled deformations that do not affect static stability

• Tested in the FLANKSOUND PROJECT by the Industrial Research Centre of the University of Bologna in accordance with EN ISO 10848

• Also tested by the ETH Institute in Zurich for fire resistance, achieving performance equal to an EI 60 solution without the need for additional fireproof sealants

• Easy to install: it can be installed with the most common construction tools

• After a stringent regulatory process, it has been tested and certified according to ETA-23/0061

The components and life cycle of XYLOFON can be found in the EPD (Enviromental Product Declaration).

Product free of harmful substances.

HOW TO CHOOSE THE RIGHT XYLOFON? WITH MYPROJECT

For proper wall soundproofing with XYLOFON, the acoustic profile with the right characteristics must be chosen. Using the Acoustics module of the MyProject design software, calculating the appropriate sound insulation for various types of structures (CLT, framed) is easy. The software offers the possibility of:

• Design sound insulation in different design frequencies

• Calculate the vibration reduction index according to the EN ISO 12354 standard

• Calculate the XYLOFON resilient profile and create a printable plan for correct installation

• Calculate the sound insulation solution both for framed structures and for structures in CLT

• Import the .dxf file with automatic recognition of walls and dimensions

• Print the technical report complete with computation and performance charts

Documents

-

Technical data sheets

-

Technical Manual

-

ETA Certificate

-

Timber connections with Xylofon

-

Environmental Product Declaration (EPD) + (LCA)

-

Fire test report

XYLOFON

| CODE | B

[mm]

|

L

[m]

|

s

[mm]

|

pcs. |

DOP

|

|---|---|---|---|---|---|

| XYL20050 | 50 | 3.66 | 6 | 1 | - |

| XYL20080 | 80 | 3.66 | 6 | 1 | - |

| XYL20100 | 100 | 3.66 | 6 | 1 | - |

| XYL20120 | 120 | 3.66 | 6 | 1 | - |

| XYL20160 | 160 | 3.66 | 6 | 1 | - |

| XYL35080 | 80 | 3.66 | 6 | 1 | |

| XYL35090 | 90 | 3.66 | 6 | 1 | |

| XYL35100 | 100 | 3.66 | 6 | 1 | |

| XYL35120 | 120 | 3.66 | 6 | 1 | |

| XYL35140 | 140 | 3.66 | 6 | 1 | |

| XYL35160 | 160 | 3.66 | 6 | 1 | |

| XYL50080 | 80 | 3.66 | 6 | 1 | |

| XYL50090 | 90 | 3.66 | 6 | 1 | |

| XYL50100 | 100 | 3.66 | 6 | 1 | |

| XYL50120 | 120 | 3.66 | 6 | 1 | |

| XYL50140 | 140 | 3.66 | 6 | 1 | |

| XYL50160 | 160 | 3.66 | 6 | 1 | |

| XYL70080 | 80 | 3.66 | 6 | 1 | |

| XYL70090 | 90 | 3.66 | 6 | 1 | |

| XYL70100 | 100 | 3.66 | 6 | 1 | |

| XYL70120 | 120 | 3.66 | 6 | 1 | |

| XYL70140 | 140 | 3.66 | 6 | 1 | |

| XYL70160 | 160 | 3.66 | 6 | 1 | |

| XYL80080 | 80 | 3.66 | 6 | 1 | |

| XYL80090 | 90 | 3.66 | 6 | 1 | |

| XYL80100 | 100 | 3.66 | 6 | 1 | |

| XYL80120 | 120 | 3.66 | 6 | 1 | |

| XYL80140 | 140 | 3.66 | 6 | 1 | |

| XYL80160 | 160 | 3.66 | 6 | 1 | |

| XYL90080 | 80 | 3.66 | 6 | 1 | |

| XYL90090 | 90 | 3.66 | 6 | 1 | |

| XYL90100 | 100 | 3.66 | 6 | 1 | |

| XYL90120 | 120 | 3.66 | 6 | 1 | |

| XYL90140 | 140 | 3.66 | 6 | 1 | |

| XYL90160 | 160 | 3.66 | 6 | 1 |

Specifications

XYLOFON

Supply and installation of high-performance resilient profile for soundproofing, type XYLOFON.

Geometry

-

B (mm) = 50 ÷ 160

-

Length L (m) = 3,66

-

s (mm) = 6

Properties

-

Acoustic improvement Δl,ij [dB]: > 7

-

Compression at 3 mm deformation (N/mm²): 3.61 ÷ 28.97

-Maximum temperature of use (°C): 200

-Reaction to fire: class E

- Water absorption after 48h: < 1%

Standards and certifications

CE marking according to ETA_23/0061

Description

High-performance resilient profile for soundproofing applications, made of high-density polyurethane, specifically designed for acoustic decoupling between structural elements in timber, steel, or concrete. Particularly suitable for the soundproofing walls and floors connected with angle brackets. Its monolithic structure ensures excellent acoustic performance by reducing vibration transmission caused by impacr sound, thus enhancing indoor comfort. It acts as a mechanical break and acoustic separation layer between different construction materials.

Installation

Suitable for application on lightweight floors, timber frames, frame systems, and massive timber elements such as CLT and LVL. It can also be installed on steel and concrete using PRIMER SPRAY or DOUBLE BAND double-sided adhesive tape. To minimise vibration transfer throughout the structure, it is recommended to install the resilient profile both above and below the floor slab.

It can also be used in dry floor systems, applied to the underside and/or top side of battens. Further details regarding installation can be found in the specific instructions provided by the supplier.