New

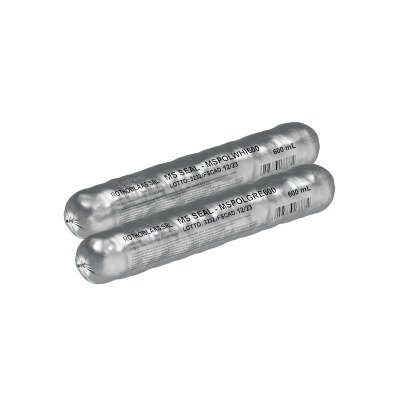

MS SEAL

MS POLYMER HIGH ELASTICITY SEALANT

MS SEAL is the universal one-component sealant ideal for gluing and sealing the most common building materials, and can be overpainted with commonly used water-based paints.

MS SEAL, the MS POLYMER sealant that ensures resistance to UV rays and ageing

Description

MS SEAL is a high-performance universal sealant with excellent ageing and UV resistance.

It is pure, single-component, with practically no shrinkage, and offers an alternative for air-tightness in the case of visible sealing. It is classified as a non-structural sealant for façade elements, for outdoor and indoor use, also in areas with cold climates (type F-EXT-INT-CC) according to EN 15651-1.

Documents

-

Technical data sheets

- Technical data sheets Croatian

- Technical data sheets Czech

- Technical data sheets English

- Technical data sheets French

- Technical data sheets German

- Technical data sheets Greek

- Technical data sheets Hungarian

- Technical data sheets Italian

- Technical data sheets Polish

- Technical data sheets Portuguese

- Technical data sheets Romanian

- Technical data sheets Russian

- Technical data sheets Slovene

- Technical data sheets Spanish

Technical Data

| Property | Standard | Tested Values | USC Conversion |

|---|---|---|---|

| Classification (1 ) | EN 15651-1 | F-EXT/INT-CC | - |

| Density | - | 1,5 g/cm³ | 0.87 oz/in³ |

| Durability | EN 15651 | compliant | - |

| Surface cross-linking time 20 °C / 50% RH (2 ) | - | 20 minutes | - |

| Time required for complete hardening 23 °C / 50% RH (2 ) | - | 2,5 days | - |

| Resistance to temperature | - | -40 / 100 °C | -40 / 212 °F |

| Application temperature (ambient, cartridge and support) (3 ) | - | 5 / 35 °C | 41 / 95 °F |

| Hardness | EN ISO 868 | 25 SHORE A | - |

| Elongation at failure | ISO 8339 | 400 % | - |

| Tensile elongation after immersion in water | ISO10590 | no failure | - |

| Tensile properties under extended pretension at -30°C | EN ISO 8340 | no failure | - |

| Elastic return | ISO 7389 | > 70 % | - |

| Vertical sliding | ISO 7390 | - | - |

| Reaction to fire | EN 13501-1 | class E | - |

| VOC emissions | EN 16516 | very low | - |

| French VOC classification | ISO 16000 | A+ | - |

| Storage temperature | - | 5 / 25 °C | 41 / 77 °F |

1.

2. The data expressed may vary depending on the thickness of the product applied and the specific installation conditions: temperature, humidity, ventilation, absorbency of the substrate.

3.