Connections for timber columns and pillars in multi-storey buildings

Speed, tolerance and the possibility for disassembly

In recent years, timber, particularly in the form of CLT, LVL and glulam, has become a leading material in construction, even in large-scale, multi-storey projects.

However, with the growing demand for speed and precision in construction – especially in large-scale buildings or public tenders with tight timelines – those working with this type of material face a constant challenge. They must develop or rethink connection and installation systems able to speed up the construction process and simplify the tasks of workers.

The solution? Leveraging new construction methods – such as Design for Assembly, or prefabrication – which enable faster on-site operations, reduce errors and ensure more precise and secure installations.

In this context, factory-installed connections can easily meet the strength requirements set by designers while also addressing the need for adaptability and practicality expressed by builders, particularly in timber structures that must compete with or complement those made of concrete or steel.

Connections in multi-storey timber buildings

Large multi-storey buildings made of reinforced concrete or steel traditionally use the “frame” system, whereby columns and beams support large floor slabs to create open-plan interior spaces free from structural constraints. In an effort to compete with these structures, timber constructions are now making use of a similar system known as “post-and-beam”. This considered, timber requires specific technical solutions to ensure efficiency in terms of:

Installation speed: Timber connections need systems that can be quickly assembled to save time on site, especially in large-scale projects.

Tolerances and precision: Timber structures must satisfy specific tolerances, taking into account the material’s natural movement.

Disassembly: Sustainability is an inherent value in Mass Timber construction, and the possibility to disassemble the structures at the end of their life cycle is an additional requirement for optimal resource management.

Prefabrication is key

In order to be competitive with other materials, timber construction must leverage its inherent strengths, most importantly, its potential for prefabrication.

The key to this system’s potential lies in the ability to pre-install the connections on walls, floors, beams and columns, subsequently enabling rapid on-site connection using simple, fast and foolproof systems.

A new family of solutions for column and beam connections has recently been developed here at Rothoblaas, using full-thread screws to pre-assemble the connectors at the factory and simple bolts to then connect them on site.

As a result, on-site installation procedures are now closely aligned with those typically used for steel or concrete buildings.

Strength, ease of assembly and precision: the ALUMEGA, RADIAL and RING range is designed to optimise prefabrication, improving overall efficiency during construction.

ALUMEGA: high-strength and flexible beam connections

Introduced to the market in 2023, ALUMEGA is the ideal solution for beam-to-beam and beam-to-column connections in structures featuring large spans. The modular components and possibility for flexible fastenings make ALUMEGA a versatile choice, even for hybrid timber-steel or timber-concrete constructions. Thanks to its hinge-like behaviour, which allows the connection to absorb movements caused by seismic forces and wind, ALUMEGA reduces the load transfer to the columns, thereby increasing the overall stability of the building. And when it comes to column-to-column connections?

RADIAL: simplicity and prefabrication for column-to-column connections

The RADIAL connector stands out for its ease of installation and its ability to fully leverage the potential of prefabrication. RADIAL consists of two semi-circular connectors pre-installed on the columns at the factory, which are then connected with a simple bolt directly on site. This configuration eliminates the need to install screws in the timber on site, thus drastically reducing the assembly time and positioning errors.

Using RADIAL for column-to-column connections allows the development of timber structures with even more advanced prefabrication, promoting extremely easy installation and column alignment without the need for complex procedures.

And to connect columns to foundations?

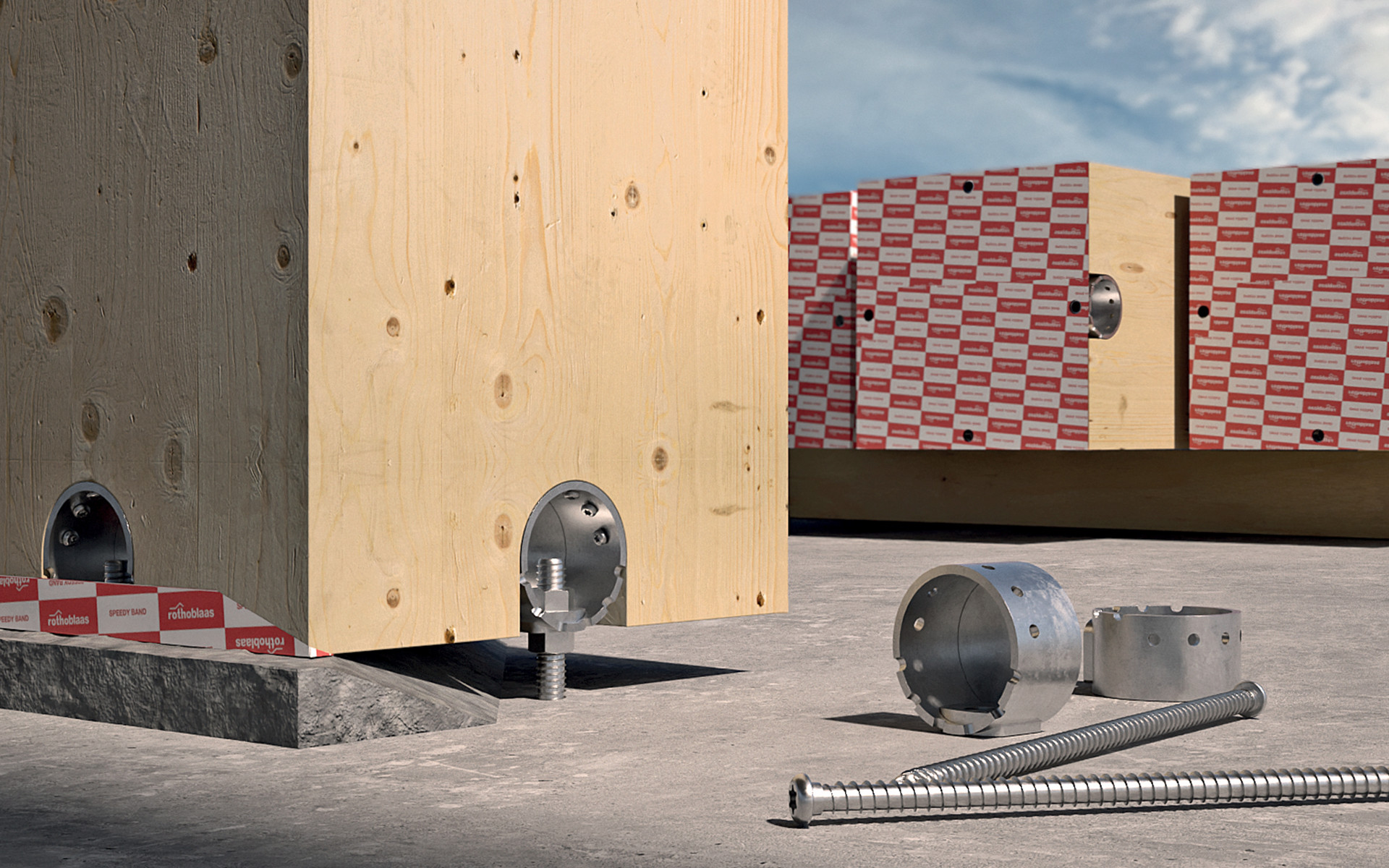

RING: stability and precision for column-to-foundation connections

The RING connector is synonymous – among other things – with guaranteed disassembly. The RING90C version is particularly suitable for column-to-foundation connections, which require the management of tolerances caused by the unevenness of the foundation itself.

Where required, this system also involves the use of shrinkage-compensating mortar to address irregularities in the base, ensuring stable and precise support for the timber columns.

A unique feature of the RING system is its adaptation, inspired by the precast reinforced concrete sector. As often occurs in concrete constructions, RING connectors can be installed on all four sides of the column, allowing for rapid on-site assembly with threaded rods and nuts that ensure precise column adjustment.

This approach helps achieve a stable, perfectly aligned structure, thus reducing the installation time.

Innovation in prefabricated connections for timber buildings

The integration of connectors like these represents a significant advancement in the efficiency of timber constructions.

ALUMEGA, RADIAL and RING solve some of the most critical challenges in the construction of multi-storey buildings, enabling the development of durable, demountable and thus more sustainable structures.

By adopting an assembly system similar to that used in steel or reinforced concrete structures, these solutions facilitate the work of professionals, cutting both construction times and costs, while also providing a viable alternative to traditional materials.

Now more than ever, timber constructions can not only compete with, but also complement concrete and steel, thanks to connection solutions that meet the safety, tolerance and assembly and disassembly needs required by the market.

There is much more to say about RADIAL, RING, and Design for Disassembly. Read the dedicated in-depth article by Andrea Polastri of the National Research Council of Italy.

All rights reserved